Fried potato chips are the most popular snacks made from fresh potatoes. They are crispy and easy to eat. Moreover, the raw potatoes used to make this snack are easily available all over the world. Therefore, the production cost of potato chips is lower, and the extreme luster is larger. The production of potato chips is profitable. The potato chip production line includes a series of potato processing machines to process fresh potatoes into packaged fried potato chips. Potato chip production has broad prospects, so what is the potato chips production line price?

Speaking of the potato chip production line cost, we should first clarify which machines are included in the potato chip production line?

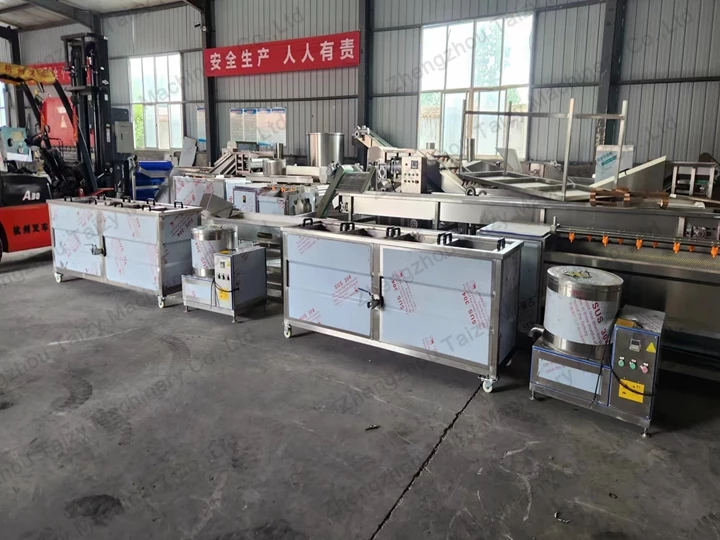

Potato chip production machine involved in the potato chip production line

The machines involved in the potato chip production line are closely related to the production steps of potato chips. The production steps of potato chips are: washing, peeling, slicing, blanching, dehydrating, frying, degreasing, seasoning, packaging and other steps.

Potato washing and peeling—There are dirt and other impurities on the fresh potatoes. Before processing the potatoes, you need to clean the impurities on the surface of the potatoes and peel them.

Slicing potatoes—After cleaning the potatoes, you need to use a potato slicer to cut the potatoes into slices of uniform thickness and size.

Blanching—Whether you make French fries or potato chips, it requires blanching potatoes. Blanching potatoes means placing potatoes in boiling water and heating them for a period of time. This step can kill bacteria and molds on the surface of potatoes. Blanching potatoes can also kill enzymes to maintain the flavor and color of the potatoes.

Dehydration—After blanching potato chips, hot water sticks to the potatoes. Therefore, it needs to be dehydrated before it can enter the next step of frying.

Frying—the temperature and time of frying potato chips determine the color, taste, and other factors of potato chips. This step is the most important step in potato chip production.

De-oiling—This step is to remove excess oil on the surface of fried potato chips to prevent greasy taste

Seasoning and packaging—The fried potato chips can be put into circulation in the market after seasoning and packaging.

The above is the brief steps of potato chip production. Potato chip production plants need to use industrial potato processing machines to process potatoes into potato chips when producing potato chips. Commercial potato chip processing machines meet each of the above steps. The potato chips production line price is also related to these commercial potato chip processing machines.

What factors determine potato chips production line price?

The final price of the potato chip production line mainly affected by factors such as the output, the involved machines, accessories, and the material of the machine.

Potato chips production line capacity

In order to meet the needs of different sizes of potato chip manufacturers, Taizy mainly provides a variety of production lines with different outputs. The potato chip production line capacity ranges from 50kg/h to 2t/h. Therefore, the potato chip line can meet the needs of large, medium, and small factories. Although the machines with different production lines are configured with the same machines, the output of potato processing machines configured on the 200kg/h production line is larger than that of the 50kg/h line.

Different involved machines with different price

Some manufacturers may own certain machines in the potato chip production line, so they may only need those machines they lack. Therefore, for different buyers, the cost of the potato chips production line is also different.

Accessories numbers

In order to increase the service life of potato chip production machines, many customers also choose to purchase machine accessories. For small potato chip production lines, customers may buy frying frames, trolleys and other accessories. For a large potato chip production line, customers may purchase oil filter, oil storage tank and other accessories. Therefore, purchasing different accessories and the number of accessories will directly affect the final potato chip production line price.

Material of potato chip production machine

The potato chip machine material is the most important factor affecting the machine price. Taizy potato chip processing machines adopt all food grade 304 stainless steel. We will provide you with high-quality potato chip machines at the most competitive price.

How to get the potato chips production line quote?

Since the potato chips production line price is affected by the above factors, we cannot directly provide you with a specific potato chip production line cost. If you want to know the specific price of the potato chip line, you can contact us for a quote. After knowing your production output and other needs, we can make a specific quotation according to your requirements. If you want to know more about our potato chip production machine, please click on the potato chip production line or contact us.