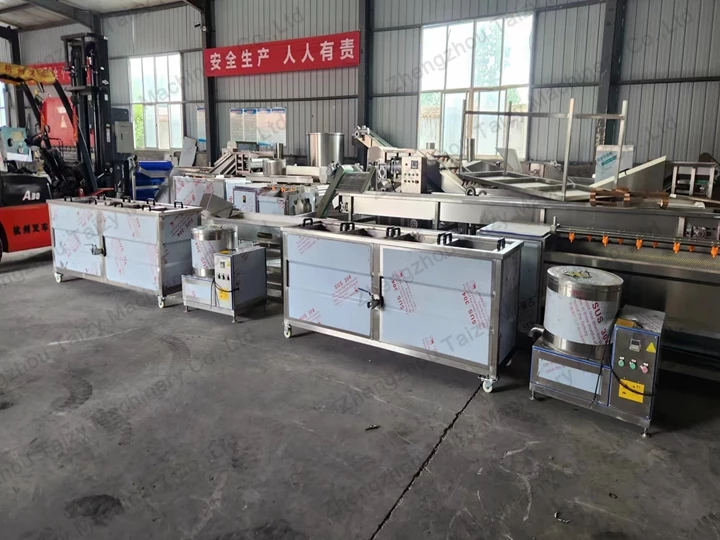

自动土豆片生产线实现连续高品质土豆片生产,节省大量人工成本。工业土豆片制作机采用304不锈钢制造,符合食品安全标准。

自动土豆片加工线适用于中小食堂、食品公司、超市、休闲食品厂、食品加工企业等。整套土豆片加工设备可根据客户的产量、性能、功能等具体需求定制。

自动土豆片生产线具有高产、投资少、能耗低、多功能、操作简便、维护方便等优点。

土豆片制作机的工艺步骤

工业 土豆片 制作机械主要包括清洗和去皮、切片、焯水、脱水、油炸、去油、调味、包装及辅助设备。

炸土豆片生产线的具体工艺流程:提升和送料→清洗去皮→挑选→提升送料→切片→冲洗→脱水→油炸→去油→调味→输送→包装。

自动土豆片生产线通过输送机和提升机实现自动送料和连续生产。

土豆片制作机工作视频

土豆片生产线的突出优势

- 全自动生产,大大减少人工和加工时间。

- 采用先进技术、严格工艺、优质产品的工业土豆片制作设备

- 投资少、能耗低、多功能

- 炸制过程中精确控制油温,确保土豆片的品质和口感。

- 多用途:除普通土豆片外,还适用于波浪土豆片、切片等。

- 多样的最终产品(光滑表面或波纹切割、不同厚度和口味)

工业土豆片加工线的主要设备

- 土豆清洗去皮机

硬刷可以在不损伤原料肉质的情况下去除原料表皮。刷子设备有正转和反转两种形式。清洗后,材料可通过刷子的旋转进行翻转和排出。

土豆清洗去皮机节水、省时,容量大。适用于土豆、胡萝卜、甜菜、芋头、莲藕等。

- 土豆切片机

切片机能快速切割,厚度可调范围为2mm至20mm。切割面平滑。土豆、红薯、芋头、萝卜、胡萝卜、木薯等原料均可用此设备切成条。特点:高效率、外形简洁、结构紧凑、操作简便。

- 土豆片焯水机

焯水的目的是去除土豆中的淀粉,以保持原始颜色。

焯水温度由电磁阀、热电偶和温控表控制;焯水时间由变频器控制,输送带速度可调。加热方式可为电加热或燃气加热。

- 空气干燥机

使用常温强力气流,空气干燥机去除土豆片或条表面的水分。该设备也常用于不同水果和蔬菜的简便包装。为了确保原料的顺畅流动,空气干燥机采用连续间歇输送系统。

- 土豆片油炸机

土豆片油炸机能够实现连续炸制,效果优良。连续油炸机配备自动温控系统,节能高效。

- 振动去油机

此类去油机常用于食品生产线,快速去除土豆片上的多余油脂,且对原料损伤较小。

- 薯片调味机

薯片调味机配有旋转鼓,实现均匀混合,支持连续加工和自动排出。

- 包装机械

土豆片包装机具有高效率和精准送料功能。在包装时,充氮气可以有效防止土豆片破碎并延长保质期。

200kg/h土豆片加工线参数

| 订单 | 名称 | 参数 |

| 1 | 土豆清洗去皮机 | 型号:TZ-800 尺寸:1600*850*800mm 电压:380V/220V 功率:0.75kw 重量:220kg |

| 2 | 土豆切片机 | 型号:TZ-600 尺寸:600*500*900mm 重量:70kg 功率:0.75KW 容量:500-800kg/h |

| 3 | 土豆焯水(电加热或燃气加热) | 型号:TZ-2000 尺寸:1500*1100*1300mm 产能:200公斤/小时 功率:5kw/h 重量:240kg |

| 4 | 空气干燥机 | 功率:3.75kw 电压:220V 380V 尺寸:3300x950x1130mm |

| 5 | 土豆片油炸机(电加热或燃气加热) | 型号:TZ-2000 尺寸:2200*700*950mm 重量:180kg 功率:42kw 容量:200-250kg/h |

| 6 | 振动去油机 | 尺寸:2400*1100mm 筛网宽度:1000mm 功率:0.25kw |

| 7 | 土豆片调味机 | 型号:TZ-2400 尺寸:2400*1000*1500mm 重量:300kg 功率:0.75kw 容量:1000kg/h |

| 8 | 土豆片包装机 | 包装速度:80次/分钟 包装重量:1000-2000g 称重精度:±0.3~1.5克 |

土豆片生产线直径注意事项:此200kg/h土豆片制作线仅为参考配置,属于小产量加工线。该系列设备有不同型号可供选择,因此我厂可根据您的具体需求设计专属的土豆片制作设备。

我公司可根据用户需求定制不同类型的工业土豆片制作机。以上为200kg/h工业土豆片生产线的通用型号。我们的专业团队可为您提供最合适的设备匹配方案及其他技术指导。