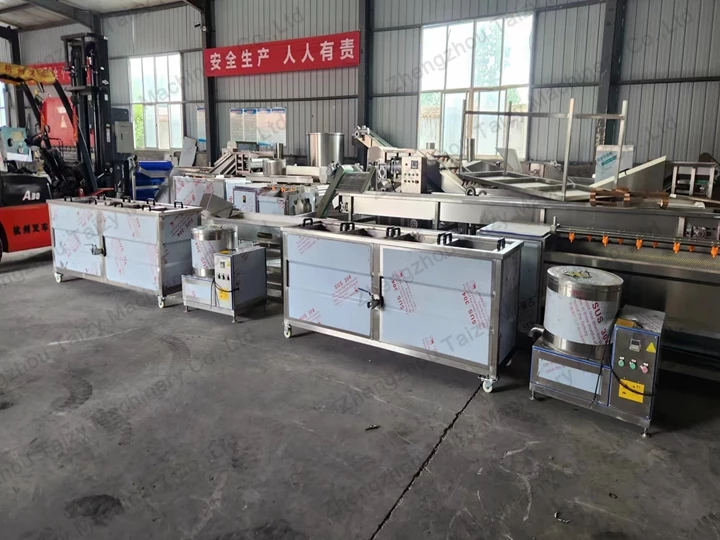

The automatic potato chip production line produces high-quality potato chips with continuous production, saving a lot of labor costs. The Industrial potato chips making machine is made of 304 stainless steel and meets food safety standards.

The automatic potato chip processing line is suitable for small and medium canteens, food companies, supermarkets, snack food factories, food processing companies, etc. The whole set of potato chip processing equipment can be customized according to the specific needs of customers for output, performance, functions, etc.

The automatic potato chip manufacturing line has the advantages of high productivity, low one-time investment, low energy consumption, multiple functions, simple operation, and convenient maintenance.

Processing steps of potato chips making machine

The processing of industrial potato chips making machines mainly consists of cleaning and peeling, slicing, blanching, dehydration, frying, degreasing, seasoning, packaging, and auxiliary equipment.

The specific process flow of fried potato chips production line: lifting and feeding → cleaning and peeling → picking → lifting feed → slicing → rinsing → dehydration → frying → deoiling → seasoning → conveying → packaging.

The automatic potato chip production line realizes automatic feeding and continuous production through conveyors and hoists.

Video of how potato chips making machine unit works

The outstanding advantages of the potato chip production line

- Fully automated production, greatly reducing labor and processing time.

- Industrial potato chips making machines manufactured by advanced technology, strict processing procedures, and high product quality

- Low one-time investment, low energy consumption, and multiple functions

- Precise control of oil temperature during frying ensures the quality and taste of potato chips.

- Multi-purpose: In addition to ordinary potato chips, it is also suitable for wave potato chips, cutting chips, etc.

- Variety of final products (smooth surface or crinkle-cut shapes, different thicknesses and flavors)

Main machines of industrial potato chips processing line

- Potato washing and peeling machine

The hard brush can remove the skins of the raw material without damage to the flesh of the raw materials. The brush device is designed in two forms: forward rotation and reverse rotation. After cleaning, the material can be rotated and discharged by the rotation of the brush.

The potato washing peeling machine is water-saving, time-saving, and with large capacity. Suitable for potatoes, carrot beets, taro, potatoes, lotus roots, etc.

- Potato slicing machine

The slicing machine quickly cut chips with adjustable thicknesses ranging from 2mm to 20mm. The cutting surface is smooth. The potato chips cutting machine is used to cut the materials like potatoes, sweet potato, taro, turnip, carrot, cassava, etc. into strips. Features: High efficiency, simple appearance, and compact structure, easy operation.

- Potato chips blanching machine

The purpose of blanching is to remove the starch of potatoes to keep the original color.

The blanching temperature is controlled by a solenoid valve, thermoelement, and temperature-controlled meter; the blanching time will be controlled by a frequency converter, and the conveying belt speed can be adjusted. The heating type can be electric heating or gas heating.

- Air dryer

Using powerful air at a regular temperature, the air drying machine removes water from the surface of potato slices or strips. This equipment is also commonly used for the easy packaging of different fruits and vegetables. To keep the raw material moving smoothly, the air dryer uses a continuous intermittent conveying system.

- Potato chips frying machine

The potato chips frying machine can realize continuous frying with a high frying effect. The continuous fryer has an automatic temperature control system that saves electricity.

- Vibration deoiling machine

This type of deoiling machine is often used in the food production line to quickly remove the extra oil on the potato chips with less damage to the materials.

- Chips flavoring machine

The chips flavoring machine has a rotary drum to realize even mixing and can realize continuous processing and automatic discharging.

- Packaging machine

The potato chip packaging machine has high efficiency and accurate feeding. When packaging, filling the packaging bag with nitrogen can effectively prevent potato chips from breaking and prolong their shelf life.

Parameter of potato chips processing line (200kg/h)

| Order | Name | Parameter |

| 1 | Potato washing and peeling machine | Model: TZ-800 Dimension:1600*850*800mm Voltage:380v/220v Power:0.75kw Weight: 220kg |

| 2 | Potato slicing machine | Model: TZ-600 Size:600*500*900mm Weight:70KG Power:0.75KW Capacity:500-800kg/h |

| 3 | Potato chips blanching (Electric or gas heating) | Model: TZ-2000 Size:1500*1100*1300mm Capacity: 200kg/h Power: 5kw/h Weight: 240kg |

| 4 | Air dryer machine | Power:3.75kw Voltage:220v 380v Dimension:3300x950x1130mm |

| 5 | Potato chips frying machine (Electric or gas heating) | Model: TZ-2000 Size:2200*700*950mm Weight:180kg Power:42kw Capacity:200-250kg/h |

| 6 | Vibration deoiling machine | Size: 2400*1100mm Screen width:1000mm Power: 0.25kw |

| 7 | Potato chips flavoring machine | Model: TZ-2400 Size: 2400*1000*1500mm Weight: 300kg Power:0.75kw Capacity:1000kg/h |

| 8 | Potato chips packaging machine | Packaging speed: 80 times/minute Packaging weight:1000- 2000g Weighing accuracy:±0.3~1.5g |

Note for the potato chips line diameter: This 200kg/h potato chips making machines line is just a reference configuration, which belongs to the processing line with small output. The machines in this line are available in different models. Therefore, our factory can design exclusive potato chips making machines for you according to your specific needs.

Our company can customize different types of industrial potato chips making machines according to users’ requirements. The above is the general type of the 200kg/h industrial potato chips line. Our professional team can offer you the most suitable machine matching plan and other technical guidance accordingly.