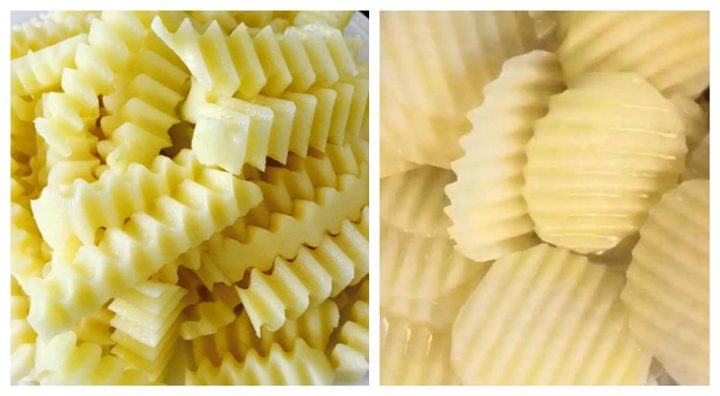

Η μηχανή κοπής κυματιστών τηγανητών, επίσης γνωστή ως πολυλειτουργική μηχανή κοπής λαχανικών, κόβει τις πατάτες σε κυματιστά σχήματα. Η μηχανή κοπής κυματιστών γαλλικών τηγανητών διαθέτει χαρακτηριστικά πολλαπλών λειτουργιών, απλής λειτουργίας, εύκολης συντήρησης, χαμηλού θορύβου, υψηλής απόδοσης και μεγάλης αποτελεσματικότητας. Το πάχος των κομμένων τσιπ ή λωρίδων πατάτας είναι ρυθμιζόμενο.

Τα τελικά φέτες και λωρίδες πατάτας είναι τακτοποιημένα, και ομοιόμορφα σε πάχος, και η ποιότητα είναι πολύ καλύτερη από αυτήν της χειροκίνητης κοπής. Η μηχανή κυματιστών κοπής πατατών μπορεί επίσης να χρησιμοποιηθεί για την κοπή άλλων ειδών λαχανικών, κατάλληλη για καντίνες, εστιατόρια, εργοστάσια επεξεργασίας λαχανικών, γραμμές παραγωγής γαλλικών τηγανητών, γραμμές παραγωγής πατατό chips, κ.λπ. Για την κατασκευή κυματιστών τηγανητών ή chips, το εργοστάσιο Taizy διαθέτει διαφορετικές μηχανές κοπής που μπορούν να επιλεγούν.

Πώς να φτιάξετε κυματιστούς γαλλικούς τηγανητούς;

Το εργοστάσιο Taizy μπορεί να παρέχει μηχανές κοπής για την ταχεία επεξεργασία κυματιστών γαλλικών τηγανητών. Η αποδοτικότητα επεξεργασίας αυτής της μηχανής κυμαίνεται από 300kg/h έως 600kg/h. Η μηχανή κοπής κυματιστών τηγανητών χρησιμοποιείται συχνά σε γραμμές παραγωγής γρήγορων κατεψυγμένων γαλλικών τηγανητών.

Εφαρμογή της μηχανής κοπής κυματιστών τηγανητών

Ο κύριος σκοπός της μηχανής κοπής κυματιστών τηγανητών περιλαμβάνει:

- Στρογγυλά φρούτα και λαχανικά, όπως πατάτα, ραπανάκι, κρεμμύδι, πιπέρι, κασάβα, ταραξ και άλλα στρογγυλά λαχανικά.

- Φύλλα λαχανικών, όπως λάχανο, σέλινο, σκόρδο, σχοινόπρασο, κ.λπ.

Διαδικασία κοπής κυματιστών τηγανητών

Υπάρχει μια περιστροφική κυλινδρική συσκευή κοπής πίσω από τη μηχανή κοπής κυματιστών τηγανητών, η οποία χρησιμοποιείται κυρίως για την κοπή. Η κυματοειδής λεπίδα μπορεί επίσης να χρησιμοποιηθεί για την κοπή κυματιστών γαλλικών τηγανητών ή πατατό chips, κ.λπ.

Πρώτα, το καθαρισμένο πατάτα τοποθετείται στην περιστροφική κυλινδρική λεκάνη της μηχανής και κόβεται απευθείας σε φέτες. Στη συνέχεια, τα υλικά πέφτουν στην ιμάντα μεταφοράς και μετακινούνται προς τις κυματοειδείς λεπίδες. Μετά από αυτό, κόβονται τα υλικά για να σχηματίσουν κυματιστούς γαλλικούς τηγανητούς.

Δομή της μηχανής κοπής κυματιστών γαλλικών τηγανητών

Αυτή η πολυλειτουργική μηχανή κοπής γαλλικών τηγανητών με κυματιστό κόψιμο είναι εξοπλισμένη με περιστροφική κυλινδρική λεκάνη, και το πάχος της κοπής είναι 2-10mm ρυθμιζόμενο. Η κυματοειδής λεπίδα μπορεί επίσης να χρησιμοποιηθεί για την κοπή κυματιστών γαλλικών τηγανητών, κυματιστών πατατό chips, κ.λπ.

Η μηχανή κοπής κυματιστών τσιπς περιλαμβάνει κυρίως το κόπτη, προστατευτικό κάλυμμα, θύρα απομάκρυνσης φέτας, πίνακα ελέγχου, προστατευτικό πλέγμα, θύρα τροφοδοσίας, ιμάντα μεταφοράς, θύρα απομάκρυνσης, βούρτσα καθαρισμού.

Αρχή λειτουργίας μηχανής κοπής λαχανικών

Η μηχανή κοπής κυματιστών τηγανητών προσομοιάζει την αρχή της χειροκίνητης κοπής και υιοθετεί τριβάθμια μεταβολή ταχύτητας για να καλύψει τις ανάγκες. Η επιφάνεια των κομμένων λαχανικών είναι λεία και κανονική.

Ο μηχανισμός περιστροφικής κοπής ολοκληρώνει την κοπή όλων των ειδών σκληρών λαχανικών, τα οποία μεταφέρονται αυτόματα στον κάθετο λεπίδα για shredding ή κοπή. Είναι κατάλληλος για την επεξεργασία σκληρών και μαλακών ριζωδών, στελεχών και φύλλων λαχανικών.

Πλεονεκτήματα μηχανής κοπής κυματιστών πατατό chips

- Υψηλής ποιότητας ανοξείδωτο ατσάλι

- Όμορφη εμφάνιση

- Απλή λειτουργία και εύκολη ρύθμιση

- Εύκολη συντήρηση, χαμηλός θόρυβος

- Υψηλή απόδοση και αποτελεσματικότητα.

- Ρυθμιζόμενα μεγέθη. Τα γενικά μεγέθη των τηγανητών είναι 7-12mm. Τα τελικά προϊόντα είναι καθαρά και ομοιόμορφου πάχους.

Παραμέτρους μηχανής κοπής κυματιστών τηγανητών

| Μοντέλο | Τάση | Ισχύς | Μέγεθος | Βάρος | Χωρητικότητα |

| Μοντέλο 600 | 220V/50HZ | 0.75kw | 900x460x740mm | 140kg | 100-600kg/h |

| 1.1kw | 220V/50HZ | 1.1kw | 380kg | 200-1000kg/h | διάμετρος κυματιστών τηγανητών |

Πώς να φτιάξετε κυματιστούς πατατό chips;

γρήγορη μηχανή κοπής κυματιστών chips

Η δομή και τα εξαρτήματα αυτής της μηχανής κοπής κυματιστών πατατό chips είναι κατασκευασμένα από υψηλής ποιότητας ανοξείδωτο ατσάλι 304, το οποίο είναι πολύ ανθεκτικό στη φθορά και στη διάβρωση.

- Αυτή η πατατομηχανή κοπής διαθέτει πολλαπλές θύρες τροφοδοσίας για την εύκολη τροφοδοσία πρώτων υλών διαφορετικών σχημάτων και μεγεθών. Επομένως, η μηχανή έχει ευρεία εφαρμογή και μπορεί να επεξεργαστεί όλα τα είδη φρούτων και λαχανικών.

- Ο κεφαλής κοπής αυτής της μηχανής μπορεί να αντικατασταθεί. Μπορούμε να επεξεργαστούμε τελικά προϊόντα διαφορετικών μεγεθών και σχημάτων αλλάζοντας διαφορετικές κεφαλές κοπής, όπως πατατό sticks, πατατό chips, πατατό κύβους, κ.λπ.

- πλάκα κοπής για την κατασκευή κυματιστών πατατό chips

Το πάχος των κυματιστών πατατό chips που επεξεργάζεται η μηχανή κοπής κυματιστών πατατό chips μπορεί να ρυθμιστεί, και οι πελάτες μπορούν να επεξεργαστούν κυματιστά πατατό chips που καλύπτουν τις ανάγκες τους σύμφωνα με τις απαιτήσεις τους.

κυματιστά chips