ポテトチップス生産ラインは、生のジャガイモからカリカリのポテトチップスを作る一連の機械を含みます。製造工程は洗浄、皮むき、スライス、ブランチング、脱水、揚げ、脱油、味付け、包装を主に含みます。

容量の違いにより、揚げポテトチップスの生産ラインは小規模ラインと完全自動ポテトチップス処理工場に分かれます。小規模ラインの容量は50kg/hから300kg/hまで、完全自動ラインは300kg/hから2t/hまでです。

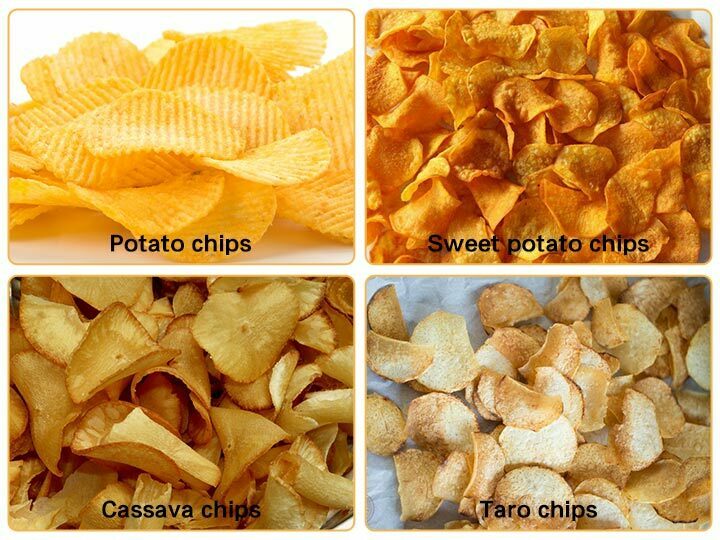

チップス機械メーカーが提供するポテトチップス処理機は、ポテトチップスだけでなく、サツマイモチップス、キャッサバチップス、タロイモチップスなども製造可能です。

ポテトチップス生産ライン

小型ポテトチップス生産ラインは主に半自動ポテトチップス製造機で構成されており、手動で給餌と排出を行います。製造工程はジャガイモの洗浄、スライス/カット、ブランチング、脱水、揚げ、脱油、味付け、包装を含みます。

半自動ポテトチップス処理工場のフローチャート

ポテト洗浄機

ポテト洗浄機の主な機能は洗浄と皮むきです。洗浄と同時に皮をむくことができ、高い洗浄効率を持ちます。9本の毛髪ロールが均等に配置されており、ジャガイモと完全に接触して表面の不純物を徹底的に洗浄します。

ポテトチップスカッター

ポテトチップススライサーはスライスとカットの機能を持ち、同じ厚さのポテトチップスを生産します。サイズや形状を変更することで、さまざまなポテトチップスの生産要件に対応可能です。特に、波型ポテトチップスも作れます。

チップブランチング機

ポテトブランチング機の主な機能は、ジャガイモのデンプンを除去し、ポテトチップスの色と味を維持することです。このポテトチップス製造機は304ステンレス鋼製で、ブランチング温度範囲は80-100℃で調整可能です。

チップ脱水機

脱水機は遠心力の原理を利用し、制御パネルで脱水時間を調整可能です。脱水時間は1〜2分です。

ポテトチップス揚げ機

ポテトチップス揚げ機は304ステンレス鋼製で、安全かつ衛生的な揚げ環境を確保します。揚げ温度は一般的に160〜180℃に維持され、揚げ時間は1〜5分です。半自動ポテトチップス生産ラインはフレームフライヤーを使用します。フレームの数が多いほど生産効率が高まります。多くの小規模ポテトチップスメーカーは複数の揚げ箱を購入し、効率を向上させています。

チップ脱油機

デオイリングマシンは脱水機と同じ動作原理を持ち、ポテトチップスの表面の余分な油を除去し、より良い味を確保します。

調味機

八角形の調味機は、回転を続けながら味付けとポテトチップスを均一に混合します。回転中でもポテトチップスを傷つけません。調味機には複数の調味ヘッドモデルもあります。液体調味料の噴霧が必要な場合は、自動調味スプレー装置も追加可能です。

ポテトチップス包装機

このポテトチップス包装機は、梱包前に梱包サイズ、重量、速度などのデータを設定できます。1分あたり25-35袋のポテトチップスを梱包可能です。包装仕様により速度は異なります。顧客は必要な包装重量を設定できます。

半自動ポテトチップス生産ラインのパラメータ

| 機械リスト | アイテム名 | 主なパラメータ |

| 1 | ポテト洗浄・皮むき機 | ロールの長さ:600-2000mm 電力:1.1-4kw 容量:500-2000kg/h |

| 2 | ポテトチップススライサー | 寸法:600*500*900mm サイズ:2-9mm 電力:1.5kw |

| 3 | ブランチング機 | 寸法:3000*1150*1250mm ベルト幅:800mm 電力:60kw |

| 4 | 水乾燥機 | サイズ:1000*500*700mm 重量:200kg 電力:1.5kw |

| 5 | ポテトチップス揚げ機 | 寸法:3000*1150*1550mm ベルト幅:800mm 電力:60kw |

| 6 | 油乾燥機 | サイズ:1000*500*700mm 重量:200kg 電力:1.5kw |

| 7 | ポテトチップス調味機 | 寸法:2400*1000*1500mm 電力:0.75kw |

| 8 | ポテトチップス包装機 | 最大重量:1000g 単一計量範囲:10-1000g 計量速度:60回/分 |

小型ポテトチップス処理ラインの動画

完全自動カリカリポテトチップス生産ライン

小型ポテト処理機と比較して、大型チップス工場は大容量のポテトチップス機に置き換えられ、多くのホイストを追加して手動の給餌と排出を自動化しています。この自動ポテトチップス処理ラインは、原料投入から揚げ、包装まで完全自動の工程を実現し、高度な自動化と広い面積をカバーします。したがって、この完全自動ポテトチップス生産ラインは大規模なポテトチップス処理工場に適しています。

完全自動ポテトチップス製造ラインの動画

大型ポテトチップス処理ラインの処理

動画から、巨大ポテトチップス生産ラインの機械は自動高容量機に置き換えられていることがわかります。

- ブランチング機と揚げ機はメッシュベルト連続機に置き換えられています。 メッシュベルトフライヤー ポテトチップスの運搬速度を制御することで揚げ時間を調整できます。PLC表示画面により揚げ時間と温度を制御し、自動昇降メッシュベルトや自動洗浄機能も備えています。

- 大型ラインでは、八角形の調味機は回転ドラム調味機に置き換えられ、連続調味と自動給餌を実現しています。

- 包装には、4頭または10頭のスケールを使用し、大容量の自動包装を実現します。

半自動ポテトチップス工場と全自動ポテトチップス生産ラインの比較

類似点

- ライン内のすべてのポテトチップス処理機は304ステンレス鋼を採用し、安全で衛生的、耐腐食性です。

- すべてのポテトチップス機械は多くのモデルがあり、さまざまな顧客のニーズに適応しています。

- 大型・小型ポテトチップスラインのフライヤーとブランチング機は電気加熱、空気加熱などの方法を採用しています。

- 両方のポテトチップス製造ラインは、スライサーマシンの刃を交換することにより、さまざまな形状とサイズのポテトチップスを製造できます。

違い

- 小規模と大規模の生産ラインは出力が異なり、小規模ラインは50-300kg/h、大規模ラインは300kg/hから2t/hまでです。

- 大型ポテトチップス生産ラインのすべての機械は、顧客の要件に応じてカスタマイズ可能です。

- 労働、敷地面積、予算、エネルギー消費に関して、2つのラインにはさまざまな違いがあります。

- 半自動ポテトチップス生産ラインは高い柔軟性を持ち、同じ機能の機械に置き換えることが可能です。そのため、小規模なポテトチップスメーカーは異なるチップス機械を購入することがあります。大型のポテトチップス工場はこれほどの柔軟性を持ちません。

- 半自動ポテトチップスラインの必要工場面積は200平方メートル未満を推奨します(50kg/hの場合約50平方メートル、100kg/hの場合約100平方メートル、200kg/hの場合約200平方メートル)。完全自動ポテトチップス生産ラインは一般的に500平方メートル以上の工場面積を必要とします。

ポテトチップス処理ラインの利点

- ポテトチップス生産ラインは出力が異なり、大規模、中規模、小規模のポテトチップスメーカーの要件を満たします。

- すべてのチップ機械は304食品グレードステンレス鋼製で、高効率、省エネ、安全性、衛生面に優れています。

- ポテトチップス生産ラインは連続作業の特性を持ち、原料から最終製品までの全工程を実現できます。

- これは、ポテトチップスの生産だけでなく、サツマイモチップス、キャッサバチップスなどの生産にも対応できるラインです。1台の機械で複数の製品のニーズを満たすことが可能です。

- この生産ラインは高い生産効率と低い投入コストを持ち、ポテトチップスメーカーにとって最適な投資選択です。

ポテトチップス生産ラインの価格はいくらですか?

ほとんどの人にとって、ポテトチップス処理ラインの価格は関心事です。ポテトチップス生産ラインはさまざまな出力を持ち、異なるコストの生産ラインがあります。さらに、顧客は他の要件やアクセサリーの購入も考慮する場合があります。したがって、ポテトチップス生産ラインの価格に影響を与える要因は多様です。

自動ポテトチップス生産ラインのパラメータ

| 項目 | パラメータ |

| ホイストコンベヤー | モデル:TZ-11 出力:0.55kw 電圧:380v/50Hz サイズ:1500*800*1600mm 重量:160kg 素材:すべてSUS 304 この機械は速度を手動で調整でき、時間とエネルギーを節約します。 |

| ねじブラシ洗浄機 | モデル:TZ-2000 出力:3.37kw 電圧:380v/50Hz サイズ:2800*1000*1400mm 重量:450kg 素材:すべてSUS 304 機械内部にはヘアローラーがあり、ジャガイモの皮を素早くこすり落とすことができます。螺旋状の研磨ローラーもあります。 |

| ピッキングコンベヤー | モデル:TZ-2500 電圧:380v/50Hz、3相 出力:0.75kw 重量:300kg サイズ:4000*700*900mm |

| 水バケットホイスト | モデル:TZ-1500 出力:0.75kw 電圧:380v/50Hz 重量:330kg サイズ:2000*950*1600mm 素材:304ステンレス鋼 |

| チップカッター | モデル:TZ-1000-1 サイズ:1000*600*1500mm チップの厚さ:2mm 素材:刃は高速ステンレス工具鋼製、ターンテーブルは高品質のアルミマグネシウム合金製、その他は304ステンレス鋼製 |

| バブル洗浄機 | モデル:TZ-3000 長さ:3m ベルト幅:800mm サイズ:3000*1200*1300mm 重量:300kg 素材:304ステンレス鋼 |

| ブランチングマシン | モデル:TZ-3500 サイズ:3000*1100*1300mm ベルト幅:800mm 加熱方式:電気 重量:300kg 2つのリフティング装置を備えたブランチングマシン |

| 脱水機 | モデル:TZ-800 出力:0.5kw 電圧:380v/50Hz サイズ:1800*1000*900mm 素材:304ステンレス鋼 |

| 空冷機 | モデル:TZ-3000-1 サイズ:3000*1200*1600mm 重量:400kg 出力:7.5kw ファン: 6 ベルト幅:800mm |

| ホイストコンベヤー | モデル:TZ-120 電力:0.75kw 電圧:380v/50Hz 重量:180kg サイズ:1500*800*1300mm 素材:304ステンレス鋼 |

| 揚げ機 | モデル:TZ-3500 サイズ:3500*1200*2400mm ベルト幅:800mm 重量:1200kg 加熱方式:電気 2つのリフティング装置を備えた揚げ機 |

| 油タンク | 油ポンプモータ出力:1.5KW/380V/50Hz サイズ:1400*1300*1850mm 素材:304ステンレス鋼 油貯蔵タンクには加熱機能、フィルター、厚さ3mmの絶縁層が装備されています。 |

| 油フィルター | 粗フィルタータンク直径:300mm 細フィルタータンクサイズ:450mm 循環ポンプ:1.5kw |

| 脱油機 | モデル:TZ-800 出力:0.5kw 電圧:380v/50Hz サイズ:1800*1000*900mm 素材:304ステンレス鋼 |

| 空冷機 | モデル:TZ-3000-1 サイズ:3000*1200*1600mm 重量:400kg 出力:7.5kw ファン:6 ベルト幅:800mm |

| ホイストコンベヤー | モデル:TZ-120 出力:0.75kw 電圧:380v/50Hz 重量:180kg サイズ:1500*800*1300mm 素材:304ステンレス鋼 |

| 調味料機 | モデル:TZ-2400 サイズ:2400*1000*1600mm 出力:1.5kw 電圧:380v、50Hz、3相 |

| 10ヘッド完全自動包装機 | A.供給コンベヤー配送 容量:3-6m³/h 電圧:380v 重量:500kg B. TZ-720縦型自動包装機 バッグ長さ:100-400mm(L) バッグ幅:180-350mm(W) ロールフィルム最大幅:720mm 梱包速度:5-50袋/分 測定範囲:6000ml(最大) 空気消費量:0.65Mpa ガス消費量:0.4m³/分 電圧:220VAC/50Hz 出力:5kw 寸法:1780*1350*1950mm C.10バケット多頭計量器 最大計量:1000g 単一計量範囲:10-1000g 計量精度:±0.3~1.5g 計量速度:最大3000cc 制御ユニット:8.4インチキースクリーン プラットフォーム非滑り性カウンタートップ、ガードレール付き、実用的で安全。 完成品コンベヤー 梱包重量:2.5kg未満 |

上記は当社のポテトチップス処理ラインの一般的な技術データを示しています。ポテトチップスマシンのメーカーとして、さまざまな容量の自動および半自動機械を提供し、顧客の要求に応えます。

補助装置も利用可能です。一般に、機械のサイズが大きいほど出力が高くなります。例えば、ポテト洗浄・皮むき機はローラーの長さによって異なります。特別なニーズに応じて、機械をカスタマイズすることも可能です。

以下は、さまざまな出力のポテトチップス処理プラントです。

ポテトチップス生産ソリューションに関するFAQ

1kgのジャガイモから何個のポテトチップスが作れますか?

0.3kgのポテトチップス。

洗濯機を使用する場合、ジャガイモはどのくらい洗えばよいですか?

使用するジャガイモの新鮮さに基づきます。新鮮なジャガイモを使用する場合、一般的に1-2分必要です。比較用ジャガイモの場合は5-6分必要です。

ブランチング時に何か追加する必要がありますか?ブランチング時間はどのくらいですか?

食用塩1kg、ピロリン酸ナトリウム0.5kg、クエン酸0.5kg、グルコース粉末1kgを追加できます。ブランチング時間は一般的に2分です。この機械にはタイマー機能があります。

揚げ時間はどのくらいですか?揚げ温度は何度ですか?

一般的な揚げ時間は5分、油温は160-180℃です。

ブランチング機とフライヤーの温度調整は可能ですか?

調整可能。

ポテトチップス製造機の材料は何ですか?

すべて304ステンレス鋼製。

工場面積に応じたカスタマイズプランはありますか?

はい、お客様の処理要件に基づき、AからZまでの完全なポテトチップスソリューションを提供します。

一般的な納期はどのくらいですか?

在庫があれば約10日、在庫がなければ一般的に15-30日かかります。