El línea de producción de papas fritas congeladas contiene máquinas de fabricación de papas fritas diseñadas profesionalmente para producir papas fritas congeladas a partir de patatas crudas. El proceso de producción de papas fritas incluye principalmente lavado y pelado de patatas, corte de papas fritas, blanqueado, secado, fritura, secado con aceite, congelación y envasado. La línea de producción de papas fritas presenta alta eficiencia, productos de alta calidad, diversas salidas, rentabilidad, operación sencilla, etc.

Según la capacidad, las plantas de procesamiento de papas fritas pueden dividirse en línea semi-automática pequeña y planta completamente automática. La capacidad general de la línea pequeña es de 50kg/h, 100kg/h, 200kg/h y 300kg/h. La capacidad de la línea automática completa de producción de papas fritas congeladas es de 300kg/h a 2t/h.

Como fabricante de líneas de producción de papas fritas, ofrecemos conjuntos completos de máquinas para hacer papas fritas, así como máquinas individuales, equipos de apoyo, y también proporcionamos máquinas personalizadas para satisfacer las necesidades del cliente. La planta de procesamiento de papas fritas es adecuada para fábricas de snacks, restaurantes, hoteles, talleres de alimentos, cadenas de comida rápida, etc.

Resumen de la línea de producción de papas fritas congeladas

Aplicación: Principalmente utilizado para producir papas fritas congeladas, chips de patata, finger chips, papas fritas.

Capacidad: La línea de producción de papas fritas tiene líneas de producción semi-automáticas y completamente automáticas. La capacidad de la línea pequeña es de 50-300kg/h, y la de la línea automática completa es de 300-2000kg/h.

Personalizado o no: sí

Verwarmingsmethode: elektrische verwarming, gasverwarming

Áreas populares: Turquía, Alemania, Italia, Argelia, Arabia Saudita, Irak y otros lugares

Proceso de producción: Elevador-limpieza y pelado-selección-corte de tiras de patata-elevador-eliminación de impurezas-blanqueado-deshidratación-fritura-desengrasado-congelación-envasado.

Video en versión 3D de la planta de procesamiento de papas fritas congeladas

Proceso de línea semi-automática de papas fritas congeladas

- Lavado y pelado de patatas

tamaño: 1600*850*800 mm

potencia: 0.75kw

capacidad: 200kg/h

peso: 280kg

La máquina de lavado y pelado de patatas tiene funciones de lavado y pelado. Las ruedas de cepillo dentro de la máquina pueden pelar completamente las patatas sin dañarlas. El tiempo de lavado es de aproximadamente 5-6 minutos.

- Krojenie frytek

tamaño: 950*800*1600mm

tamaño de corte: 6*6mm a máximo 15*15mm (puede ser personalizado)

potencia: 1.1kw

capacidad: 600-800kg/h

Esta máquina cortadora de papas fritas está diseñada para cortar patatas en tiras. Primero, las patatas se cortan en rebanadas y luego en tiras. El tamaño de la tira de patata es ajustable, lograble cambiando la separación entre las cuchillas. Generalmente, la mayoría de los clientes prefieren tamaños de 8*8mm y 9*9mm, con un rango de 6*6mm a un máximo de 15*15mm. Además, las cuchillas son piezas vulnerables, por lo que recomiendo encarecidamente comprar cuchillas adicionales.

- Blanqueado

tamaño: 1200*700*950mm

potencia: 12kw

peso: 120kg

capacidad: 100 kg/h

La máquina de blanqueado elimina el almidón de las tiras de patata para que las papas fritas finales tengan un color brillante y mejor sabor. Su modo de calefacción incluye calefacción eléctrica y de gas, y puede elegir cualquiera según su situación. La temperatura de blanqueado es de 80-100℃. Cuenta con un sistema de control de temperatura automático y la temperatura es ajustable.

- Deshidratación

tamaño: 1100*500*850mm

potencia: 1.5kw

peso: 150kg

capacidad: 200kg/h

La máquina de deshidratación puede prevenir que la superficie de las papas blanqueadas contenga demasiada agua y salpicaduras. Utiliza el principio centrífugo para deshidratar, y el tiempo de deshidratación puede ser programado. Generalmente, el tiempo de blanqueado es de 1 a 2 minutos. Además, una máquina de secado por aire se usa frecuentemente en la línea de producción de papas fritas congeladas, que puede eliminar continuamente el agua de la superficie de las tiras de patata con aire potente.

- Fritura de papas fritas

tamaño: 1200*700*950mm

potencia: 24kw

peso: 120kg

capacidad: 100 kg/h

Freír es un paso importante en la línea de producción de papas fritas congeladas. La temperatura de fritura de 160-180℃ y las tiras de patata necesitan freírse durante 40-60 segundos. Esta máquina de fritura de papas fritas tiene una calidad superior en comparación con otras máquinas en el mercado.

- Desgrasado de papas fritas

tamaño: 1100*500*850mm

potencia: 1.5kw

peso: 350kg

capacidad: 200kg/h

Después de freír, se debe usar una máquina de desgrasado para eliminar el exceso de aceite en la superficie de las tiras de patata fritas. La máquina de desgrasado es igual a la máquina de deshidratación.

- Papas fritas congeladas

A máquina de congelación rápida para congelar las papas fritas fritas, evitando que se peguen entre sí al envasarlas. El tiempo de congelación es de 20-30 minutos, y la temperatura mínima es de -45℃. Las papas fritas que comemos en McDonald's se vuelven a freír después de salir de la máquina de congelación. El tamaño de la máquina puede ser personalizado según los requisitos.

- Envasado de papas fritas

Una máquina de envasado de papas fritas para empacar diversos snacks, con funciones múltiples de pesaje automático, envasado y sellado. Ofrecemos máquinas de envasado al vacío para papas chips y máquinas de envasado de papas en diez cubetas.

Video de funcionamiento de la línea semi-automática de papas fritas

Características de las máquinas de procesamiento de papas fritas a pequeña escala

Nuestra línea de producción pequeña de papas fritas congeladas tiene muchas características sobresalientes:

1. La máquina de limpieza de patatas en la línea pequeña de producción de papas fritas congeladas tiene funciones de limpieza y pelado. La rueda de cepillo dentro de la máquina puede pelar completamente las patatas sin dañarlas. El tiempo de lavado es de aproximadamente 5-6 minutos. Además, también puede limpiar otras frutas y verduras como jengibre, dátiles y zanahorias.

2. La máquina cortadora de papas fritas en la línea semi-automática de producción de papas fritas congeladas está fabricada con componentes importados de Taiwán. Su rango de corte es de 6*6mm a 15*15mm. Por supuesto, podemos personalizar múltiples cuchillas de diferentes tamaños de corte según las necesidades del cliente. Cambiando la cuchilla, se puede usar una sola cortadora para hacer diferentes tamaños de papas fritas.

3. Tanto la máquina de blanqueado como la de fritura en esta línea de producción tienen métodos de calefacción eléctrica y de gas. Sus tubos de calefacción eléctrica están compuestos por tubos de calefacción sin costura, y su potencia es baja. El uso de tubos de calefacción sin costura permite que la máquina de blanqueado y la freidora tengan funciones seguras y eficientes.

4. El congelador es la máquina más importante que distingue la línea de producción de papas fritas congeladas de la línea de producción de patatas fritas. El congelador puede ser equipado según las necesidades del cliente.

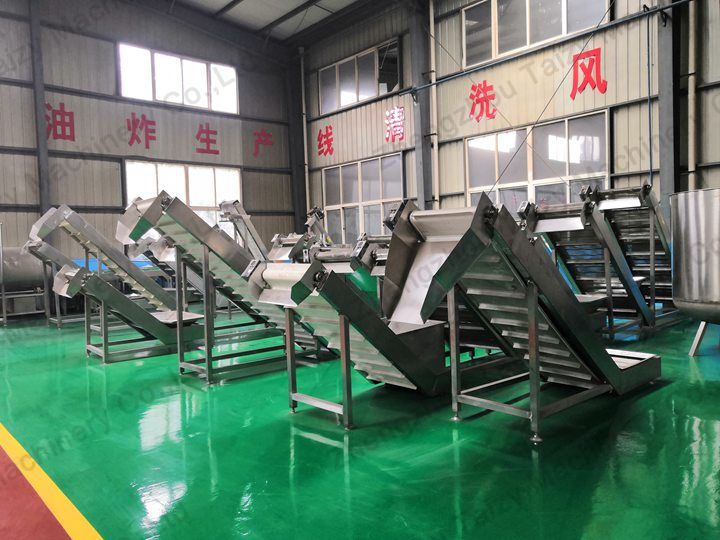

Máquina semi-automática de procesamiento de papas fritas congeladas de 100kg/h

Proceso de línea automática completa de papas fritas

En comparación con la línea semi-automática de papas fritas congeladas, la línea automática reemplaza la máquina de papas fritas automática. Además, también añade una máquina de recogida de papas fritas y una máquina de lavado antes de la máquina de blanqueado.

Y esto es lo que distingue la línea de producción de papas fritas congeladas de la línea de chips de patata. También puede producir chips de patata añadiendo o reduciendo máquinas individuales en base a la línea de papas fritas.

La máquina requerida en la planta de procesamiento automático de papas fritas congeladas

Como se muestra en la tabla, hay una serie de máquinas con parámetros típicos en la línea de producción automática de papas fritas congeladas. En comparación con una planta de procesamiento semi-automática, se utilizan varios elevadores, transportadores, y diferentes tipos de máquinas de secado y envasado para realizar una producción continua y reducir la mano de obra. Las máquinas principales y el equipo de apoyo pueden ajustarse de manera flexible según las necesidades reales.

| 项目 | Imagen | Parametere |

| 1. elevador |  | Modelo: TZ-100 功率:0.55kw 电压:380V/50Hz Teža: 180 kg 尺寸:1500*800*1600mm Velocidad de la cinta: ajustable 材质:304不锈钢 |

| 2. lavado y pelado |  | Modelo: TZ-2600 Potencia: 4.37kw 电压:380V/50Hz Peso: 480kg Tamaño: 3400*1000*1400mm Velocidad del tornillo interior: ajustable Capacidad: 2400kg/h 材质:304不锈钢 |

| 3. cinta transportadora de recogida |  | Modelo: TZ-110 Moč: 0,75 kW 电压:380V/50Hz Peso: 280kg Tamaño: 3500*800*900mm Velocidad de la cinta: ajustable 材质:304不锈钢 |

| 4. cortadora de patatas |  | Model: TZ-600 Snaga: 1.1kw 电压:380V/50Hz Peso: 120kg Tamaño: 950*800*950mm Uwezo: 600kg/h 材质:304不锈钢 Notas: el precio solo incluye 1 juego de cuchillas, si desea un tamaño diferente, cambie la cuchilla. |

| 5. elevador de cubo de agua |  | Modelo: TZ-200 Moč: 0,75 kW 电压:380V/50Hz 重量:330kg 尺寸:1500*800*1600mm Cinta transportadora: 500mm 材质:304不锈钢 |

| 6. máquina de selección |  | Modelo: TZ-1400 Tamaño: 2400*1000*1300mm Snaga: 1.1kw 电压:380V/50Hz 材质:304不锈钢 Función: Seleccionar un tamaño de patata diferente, lo que hará que el tamaño final de la patata sea el mismo. |

| 7. máquina elevadora |  | Modelo: TZ-4000 Potencia: 4.1kw 电压:380V/50Hz 重量:400kg Capacidad: 800kg/h Tamaño: 4000*1200*1300mm Ballaca suunka: 800mm 材质:304不锈钢 |

| 8. máquina de blanqueado |  | Modelo: TZ-6000 peso: 1200kg tamaño: 5000*1200*2400mm Uwezo: 600kg/h Temperatura: 95 grados 带宽:800mm Tipo de calefacción: eléctrico potencia: 500000kcal 材质:304不锈钢 |

| 9. removedor de vibración de agua |  | Model: TZ-800 功率:0.5kw 电压:380V/50Hz 尺寸:1800*1000*900mm 材质:304不锈钢 |

| 10. enfriador de aire |  | Modelo: TZ-300 Potencia: 6.5kw 电压:380V/50Hz Peso: 700kg Tamaño: 4000*1200*1600mm Ventilador: 8 piezas Potencia del ventilador: 0.75kw Presión del viento: 120pa Velocidad: 2800r/min Ballaca suunka: 800mm 材质:304不锈钢 |

| 11. elevador |  | 型号:TZ-120 Moč: 0,75 kW 电压:380V/50Hz Teža: 180 kg 尺寸:1500*800*1300mm 材质:304不锈钢 |

| 12. máquina de fritura |  | Modelo: TZ-6000 peso: 1200kg tamaño: 6000*1200*2400mm Uwezo: 600kg/h temperatura: 95 grados 带宽:800mm Tipo de calefacción: eléctrica Potencia del quemador: 500000kcal Marca del quemador: Italia liya road 材质:304不锈钢 |

| 13. tanque de aceite |  | 油泵电机功率:1.5KW/380V/50Hz 尺寸:1400*1300*1850mm Material: acero inoxidable 304, el tanque de almacenamiento de aceite está equipado con función de calefacción, con filtro, y un grosor de 3mm, con capa de aislamiento. |

| 14. Filtro de aceite |  | 粗滤器罐直径:300mm 细滤器罐尺寸:450mm 循环泵:1.5kw |

| 15. tanque de combustible |  | 1. El tanque de combustible está equipado con un dispositivo de calefacción. 2. El aceite que necesita ser añadido se calienta a una temperatura determinada mediante el tubo de calefacción y luego se envía al interior de la freidora mediante una bomba de circulación para lograr el propósito de añadir aceite. |

| 16. removedor de vibración de aceite |  | Model: TZ-800 功率:0.5kw 电压:380V/50Hz 尺寸:1800*1000*900mm 材质:304不锈钢 |

| 17. enfriador de aire |  | Modelo: TZ-300 Potencia: 6.5kw 电压:380V/50Hz Peso: 700kg Tamaño: 4000*1200*1600mm Ventilador: 8 piezas Potencia del ventilador: 0.75kw Presión del viento: 120pa Velocidad: 2800r/min Ballaca suunka: 800mm 材质:304不锈钢 |

| 18. elevador |  | 型号:TZ-120 Moč: 0,75 kW 电压:380V/50Hz Teža: 180 kg 尺寸:1500*800*1300mm 材质:304不锈钢 |

| 19. congelador |  | Modelo: TZ-10000 Dimensiones exteriores: 160000*3300*2600mm Compresor: 150hp Potencia de la malla: 2.2kw Ventilador: 12pcs * 1.5kw Motor de la cinta de malla: Siemens PLC: Siemens SUS 304 Grosor de la caja interior: 0.8mm Grosor externo: 0.8mm Interior Aislamiento de algodón; 120mm Compresor: Alemania Bitzer Una unidad: 30P, en total 3 unidades en paralelo Nota: Precio con compresor incluido |

| 20. máquina de envasado |  | A. cinta transportadora de alimentación Valor de entrega: 3-6m³/h 电压:380V 重量:500kg B. Máquina de envasado vertical TZ-720 袋长:100-400mm(L) 袋宽:180-350mm(W) 最大卷膜宽度:720mm 包装速度:5-50袋/分钟 测量范围:6000ml(最大) 气体消耗:0.65Mpa 气体消耗:0.4m³/分钟 电压:220VAC/50Hz 功率:5kw 尺寸:1780*1350*1950mm Notas: Incluye bolsa de formador C. Máquina de peso múltiple con 10 cubetas 最大称重:1000g 单次称重范围:10-1000g Natančnost tehtanja: ±0,3~1,5 g 称重速度:最大3000cc 控制单元:8.4英寸触摸屏 C. Plataforma con 10 cubetas, máquina de peso múltiple E.成品输送线 |

| 21. fAlmacenamiento de congelación de papas fritas 10 toneladas, -20°C |  | Tamaño: 5*5*2.4m Tablero de aislamiento de acero pintado de 100mm, poliuretano: 98m² Kumen: 1 La unidad aumenta la disipación de calor de 80 radiadores 8 caballos: 1 conjunto Enfriador de aire: 1 Armario de control de descongelación automática por computadora: 1 conjunto Válvula solenoide: 1 Valve ya upanuzi: 1 Freoni: 25kg Konektori za mwili wa Maktaba na vifaa vya kufunika na kuimarisha: 71m² Mstari wa mabomba na taa zinazozuia unyevu, n.k.: kundi 1 Mfumo wa mabomba na insulation: seti 1 |

Video de funcionamiento de la línea automática completa de papas fritas congeladas

Características de la línea automática de papas fritas

- Mstari wa uzalishaji wa viazi vya kukaanga kiotomatiki kamili, unaongeza lifti nyingi zinazounganisha mashine mbili za usindikaji wa viazi kiotomatiki. Kwa hivyo, mstari wa uzalishaji wa viazi vya kukaanga kiotomatiki unahitaji watu mmoja au wawili tu kudhibiti skrini ya kuonyesha ya mashine kufanya kazi.

- Ili kusafisha kwa kina uchafu kwenye viazi vya kukaanga, mstari wa uzalishaji unaongeza mashine ya kuosha kwa kuchagua saizi ya viazi vya kidole. Mashine ya kuchagua inaweza kuchuja viazi vya kukaanga vya saizi inayofaa, na viazi vidogo vitashushwa. Hii inahakikisha ubora wa viazi vya kukaanga. Mashine hii pia ni ishara kubwa inayotofautisha kiwanda cha viazi vya kukaanga na mstari wa chips.

- Inatumia mashine ya kuondoa maji na mafuta kwa kupiga kelele katika kiwanda cha usindikaji. Ikilinganishwa na mstari wa viazi vidogo, inaweza kusafirisha viazi kwa mashine inayofuata huku ikitimiza kazi za kuondoa maji na mafuta. Na inaweza kutimiza kazi ya kukusanya maji au mafuta kiotomatiki.

- Mstari wa uzalishaji wa viazi vya kukaanga vilivyogandishwa kiotomatiki kamili unatumia mashine ya kuchemsha kwa mfululizo na kukaanga kwa viazi vya kukaanga. Mashine ina kazi za uhamishaji wa kiotomatiki wa malighafi, udhibiti wa joto na muda wa kukaanga, usafi wa chini wa mashine kiotomatiki, na ukusanyaji wa moshi wa mafuta.

- Saizi ya friza ya viazi vilivyogandishwa inapaswa kuamuliwa kulingana na uzalishaji wa mteja. Aidha, tunatoa aina mbalimbali za mashine za ufungaji, ambazo zinaweza kufanikisha ufungaji wa kiasi kikubwa, kwa mfululizo, na kwa kiasi kikubwa. Mteja anahitaji kutoa saizi na uzito wa ufungaji.

Precauciones para desarrollar el negocio de papas fritas congeladas

1. Kwanza kabisa, unapaswa kujua wazi bidhaa ya mwisho unayotaka kutengeneza na saizi yake. Saizi za viazi vilivyogandishwa vya kukaanga katika maeneo tofauti si sawa kabisa. Saizi maarufu zaidi ya viazi vya kukaanga ni 3-7mm, lakini kuna tofauti fulani katika saizi maarufu zaidi mahali tofauti.

2. Kabla ya kuanza biashara ya uzalishaji wa viazi vya kukaanga, unapaswa kufanya utafiti wa kina wa soko la viazi la eneo lako ili kupata faida kutokana na uzalishaji wa viazi. Kwa mfano, aina za viazi na bei zao, upatikanaji, n.k.

3. Unaweza kuchagua mstari wa uzalishaji wa viazi vya kukaanga unaofaa hali ya kiwanda chako au bajeti yako. Bila kujali mstari wa uzalishaji unaouchagua, tunaweza kutengeneza mpango wa uzalishaji wa kipekee kwa ajili yako kulingana na kiwanda chako.

¿Cómo comenzar un negocio de papas fritas durante una pandemia?

Durante la pandemia, la producción y ventas de muchas fábricas se han visto afectadas en cierta medida. Sin embargo, algunas marcas populares han logrado expandir su negocio. Es útil conocer estrategias efectivas para el inicio del negocio de papas fritas durante la pandemia para hacer crecer su negocio.

Casos específicos de ventas de líneas de producción de papas fritas congeladas

Visiškai automatizuota fritirų gamybos linija, veikianti Turkijoje

Mašina na pomfrit u Australiji

Wateja wa Misri walitembelea kiwanda chetu cha mashine za kutengeneza viazi vya kukaanga

Bienvenido a visitar la fábrica de máquinas de papas fritas Taizy