Professional supplier of potato chip making machines

- Fully automatic French fries making machines

- Semi-automatic French fries making machines

- Fully automatic potato chip making machines

- Semi-automatic potato chip making machines

- Customized specifications and output

Taizy Machinery

Taizy Machinery is a professional manufacturer of French fries and potato chip processing machinery and equipment. Over the past 20 years, we have focused on the research and development of high-quality food processing equipment and have gained the trust of customers through high-quality service and product quality.

Productielijn voor friet

In general, the French Fries production line has semi-automatic and fully automatic types, with capacities ranging from 200kg/h to 2t/h. What is the difference between these two lines? The main difference is that the fully automatic French Fries production line can significantly save time and energy, as it includes conveyor belts between machines. We will customize the appropriate line according to your capacity requirements.

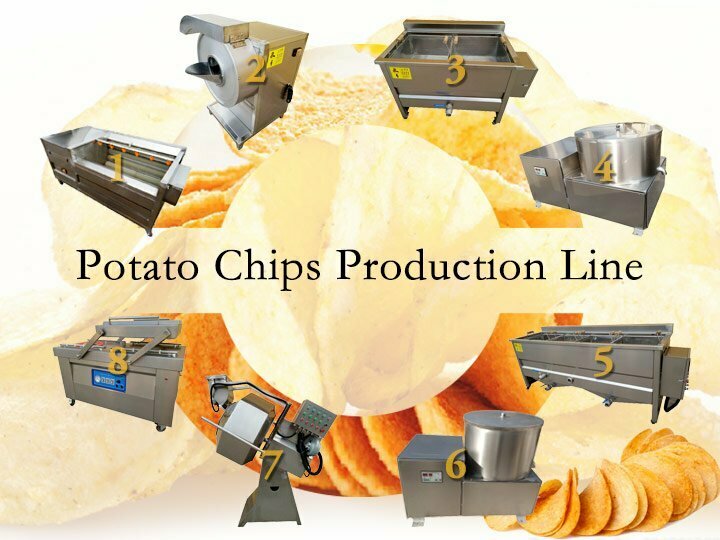

Potato chips production line

The machines between the Potato Chips Production Line and the French Fries Production Line are similar. The difference lies in the potato cutter machine. In the French Fries Production Line, we need to cut the potatoes into strips, while in the Potato Chips Production Line, the potatoes need to be cut into slices. Additionally, you should season potato chips with different flavors using the seasoning machine.

Banana slicer production line

The Banana Slicer Production Line also has semi-automatic and fully automatic types. We recommend purchasing a semi-automatic machine if your budget is limited. Unlike the French Fries production line, the banana slicing line requires a banana peeling machine. The fried banana slices are quite delicious and have a bright color.

What should you note during Potato Chips (French Fries) Production Line operation?

01.

How long does a 200kg brush-type cleaning machine take to clean potatoes? How many potatoes should I place each time?

Fresh potatoes generally need to be cleaned for 1-2 minutes. If the potatoes are stored for a long time, you should clean them for 5-6 minutes. You can place about 40kg of potatoes into the machine each time.

02.

What ingredients should be added during blanching? How long does blanching last?

1kg edible salt, 0.5kg sodium pyrophosphate, 0.5kg citric acid, and 1kg glucose powder. The blanching time is 1-2 minutes.

03.

How long is the frying process? What is the frying temperature?

40-40 seconds for general frying, oil temperature is 160-180 ℃.

04.

What is the sequence of freezing and packing?

You should first freeze the potato chips (French Fries) before packing, which can prevent the fries from sticking together. If you pack them first and then freeze, they cannot be separated.

05.

What is the working temperature of the quick freezer? What is the temperature of the final French fries?

The working temperature is -40 ℃, and the temperature of frozen fries is -(12-18) ℃.

Relying on advanced technical expertise, Taizy company has introduced modern production equipment, strictly adhering to internationally recognized scientific production process standards. In recent years, we have exported numerous fully automatic French fries production lines to new and returning customers. Guided by the pursuit of technological development and quality survival, we continuously expand our market. We have earned consumer praise through first-class products and excellent after-sales service.