Liten potetgullfremstillingslinje er en semi-automatisk potetgullfabrikk med en produksjon på 50kg/h til 300kg/h. Med moderat investering og et relativt lite fotavtrykk, er den småskala potetgulllinjen egnet utstyr for små potetgullfabrikker eller nye oppstartsselskaper. Som en erfaren produsent av matmaskineri har Taizy Machinery designet og utviklet en rekke potetgullproduksjonslinjer og pommes frites-behandlingsmaskiner, som har blitt solgt til et stort antall land.

Maskinintroduksjon av liten potetgullfremstillingslinje

50k/h potetgullbehandlingsanlegget er den mest grunnleggende konfigurasjonen for industriell behandling av potetgull, og er svært egnet for små og mellomstore matfabrikker og nye forretningsinvesteringer.

Dette skyldes at potetgullfremstillingslinjen har alle funksjoner for å produsere fritert potetgull, men på grunn av sin lille produksjonsskala er investeringskostnaden relativt lav.

Produksjonsprosessen inkluderer hovedsakelig potetvask og skrelling, potetskivning, blanchering, dehydrering, fritering av potetgull, avfetting, kryddering av potetgull, og pakking av potetgull, osv.

Potetrensings- og skrellemaskin: etter at potetene er hellet i mataren, blir de rengjort og skrelt samtidig.

Potetgullskjærer: setter de skrelte potetene inn i inntaket kontinuerlig, og potetgullet kuttes ut automatisk.

Blancheringsmaskin: fjerner stivelse fra potetgull med varmt vann.

Vann-tørkemaskin: for å tørke overflødig vann på overflaten av chipsene.

Potetgullfritør: for å fritere potetgull.

Oljetørkemaskin: tørker oljen på overflaten av fritert potetgull for å forbedre smaken.

Kryddelinje: for å smaksette de friterte potetgullene raskt.

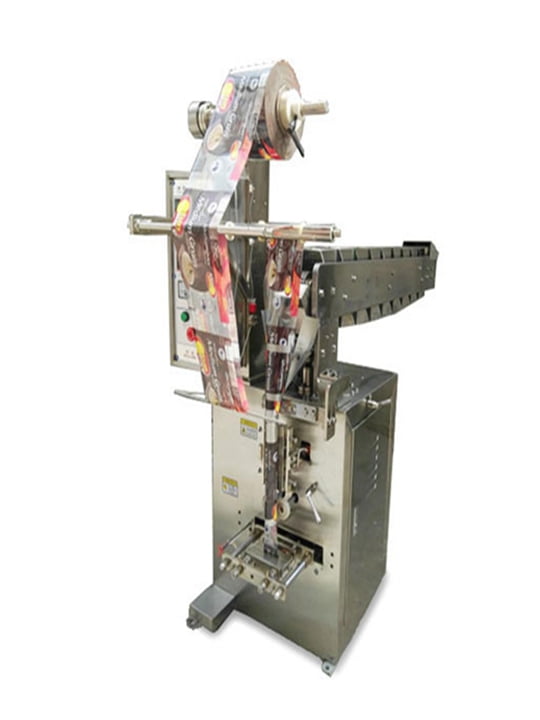

Pakke-maskin: Pakker potetgull i en bestemt volum for bedre lagring.

Fremhevinger ved potetgullfremstilling

- Fleksibel produksjon

- Plassbesparende

- Arbeidsbesparende og energisparende

- Moderat kostnad og raskt avkastningspotensial

- Hygienisk og holdbar

- Različne končne izdelke (gladka površina ali valoviti obliki, različne debeline in okusi)

- Denne lille potetgullbehandlingslinjen er en semi-automatisk behandlingsform. I produksjonen av fritert potetgull trenger hele produksjonslinjen omtrent 4-5 arbeidere.

Spesifikasjon av 50kg/h potetgullfremstillingslinje

| Antall | Maskin liste | Parametere |

| 1 | Potetvask- og skrellingsmaskin | Dimensjon: 2200*850*900mm Lengde på rulle: 1200mm Effekt: 2,95kw |

| 2 | Potetgullskjæringsmaskin | Dimensjon: 600*500*900mm Cabbirka: 2-9mm Koronto: 1.5kw |

| 3 | Mashiinka blanching | Dimensjon: 2500*950*1250mm Båndbredde: 600mm Effekt: 48kw |

| 4 | Vann-tørkemaskin | cabbirka: 1000*500*700mm miisaanka: 200kg koronto: 1.5kw |

| 5 | Potetgullfritør | Dimensjon: 2500*1200*1550mm Båndbredde: 600mm Effekt: 48kw |

| 6 | Oljetørkemaskin | cabbirka: 1000*500*700mm miisaanka: 200kg koronto: 1.5kw |

| 7 | Potetgullkryddermaskin | Dimensjon: 1400*800*1550mm Effekt: 0,75kw |

| 8 | Potetgullpakkeringsmaskin | Miisaanka ugu badan: 1000g Xadka miisaanka halbeegga: 10-1000g Xawaaraha miisaanka: 60 jeer/min |

Levering av potetgullfabrikker til utenlandske kunder

Alle slags potetgullbehandlingsløsninger er tilgjengelige i Taizy-fabrikken, for eksempel 50kg/h potetgulllinje, 100kg/h automatisk potetgullbehandlingslinje, 200kg/h semi-automatisk potetgullfabrikk, 300kg/h automatisk potetgullprosjekt, 500kg/h-1t/h fritert chipsfabrikker, osv.

Den store potetgullproduksjonslinjen har blitt eksportert til mer enn 30 land og regioner. Blant dem inkluderer de land vi ofte samarbeider med USA, Mexico, Argentina, Sør-Afrika, Uganda, Saudi-Arabia, Sverige, Storbritannia, Usbekistan, Indonesia, Thailand, osv.