The potato chips production line contains a series of potato chips machines to make crispy potato chips from raw potatoes. The potato chips manufacturing process mainly includes washing, peeling, slicing, blanching, dewatering, frying, deoiling, flavoring, and packaging.

According to the capacity difference, the fried potato chips production line includes a small chips production line and a fully automatic potato chips processing plant. The small chips line’s capacity ranges from 50kg/h to 300kg/h, while the automatic chips processing plant’s capacity range from 300kg/h to 2t/h.

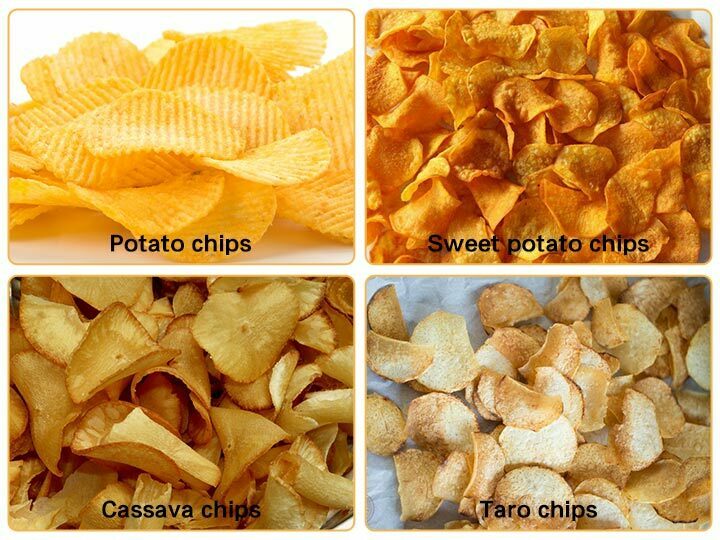

The potato chip processing machine provided by chips machine manufacturers not only can make potato chips, but also sweet potato chips, cassava chips, taro potato chips, etc. The potato chips making machine is popularly applied in restaurants, fast food stores, hotels, canteens, snack food processing factories, etc.

Potato chips production line

The small potato chips production line is mainly composed of semi-automatic potato chips making machines, they need people to manually operate the feeding and discharging. The chips manufacturing process contains washing potatoes, potato slicing/cutting, blanching potato chips, chips dewatering, potato chips frying, chips deoiling, seasoning chips, and packaging.

Semi-automatic potato chips processing plant flow chart

Potato cleaning machine

The main functions of the potato cleaning machine are cleaning and peeling. It can peel off the potatoes while cleaning and has a high cleaning efficiency. The machine consists of 9 hair rollers evenly distributed inside the machine. So it can fully contact the potatoes and thoroughly clean up the impurities on the surface of the potatoes.

potato chips cutting machine

The potato chip slicer machine has the functions of slicing and cutting. The potato chips produced by this machine have the same thickness and complete dicing. You can also meet the production requirements of various potato chip sizes by changing to other sizes and shapes. It is worth mentioning that the potato chip slicer can also be used to make wave potato chips.

chips blanching machine

The main function of potato blanching machine is to remove the starch in the potato to maintain the bright color and taste of the potato chips. This potato chips making machine is made of all 304 stainless steel, and the blanching temperature range is 80-100℃ and can be adjusted.

chips dewatering machine

The dehydrator uses the principle of centrifugation for dehydration. The machine control panel makes the dehydration time adjustable. The dehydration time is 1 to 2 minutes.

potato chips frying machine

The potato chip frying machine is made of all 304 stainless steel, so it can ensure a safe and hygienic environment for frying. The frying temperature of potato chips is generally maintained at 160~180℃, and the frying time is 1-5 minutes. The semi automatic potato chips production line uses a frame fryer. The more frames the machine has, the higher its production efficiency. In order to improve production efficiency, most small potato chip manufacturers often purchase multiple frying boxes.

mašina za uklanjanje ulja sa čipsa

The chip deoiling machine has the same working principle as the dehydrator. Its purpose is to remove excess oil on the surface of potato chips to ensure a better taste.

seasoning machine

The octagonal seasoning machine evenly mixes the flavoring and potato chips by rotating continuously. Although the machine is constantly rotating, it will not damage the potato chips. The flavoring machine also has multiple seasoning head models. If you need to spray liquid seasoning, the machine can also add an automatic seasoning spraying device to achieve high automation.

potato chips packing machine

This potato chips packaging machine can be set with all the data before packing, such as the packing size, packing weight, packing speed, etc. This potato chip packing machine can pack 25-35 bags of potato chips per minute. Due to different packaging specifications, the packaging speed is different. Customers can set their own required packaging weight.

Parameters of semi-automatic potato chips production line

| Machine list | Magaca alaabta | Astaamaha waaweyn |

| 1 | Potato washing & peeling machine | Length of roller: 600-2000mm Power: 1.1-4kw Capacity: 500-2000kg/h |

| 2 | Potetgullskjæringsmaskin | Cabbirka: 600*500*900mm Cabbirka: 2-9mm Koronto: 1.5kw |

| 3 | Potato blanching machine | Cabbirka: 3000*1150*1250mm Ballaca suunka: 800mm Koronto: 60kw |

| 4 | Mashiinka qalajinta biyaha | cabbirka: 1000*500*700mm miisaanka: 200kg koronto: 1.5kw |

| 5 | Potato Chips Frying machine | Cabbirka: 3000*1150*1550mm Ballaca suunka: 800mm Koronto: 60kw |

| 6 | Mashiinka qalajinta saliidda | cabbirka: 1000*500*700mm weight: 200kg koronto: 1.5kw |

| 7 | Potato chips Seasoning machine | Dimension: 2400*1000*1500 Effekt: 0,75kw |

| 8 | Stroj za pakiranje čipsov | Miisaanka ugu badan: 1000g Xadka miisaanka halbeegga: 10-1000g Xawaaraha miisaanka: 60 jeer/min |

Small potato chips processing line video

Fully automatic crispy potato chips production line

Compared with small potato processing machines, the large chips plant replaced a large-capacity potato chips machine. And in this line, many hoists are added to replace manual feeding and discharging. This automatic potato chip processing line can realize the fully automatic process from raw material feeding to frying and packaging. It has a high degree of automation and covers a wide area. Therefore, this fully automatic potato chips production line is suitable for large potato chip processing plants.

Fully automatic potato chips production line video

Large potato chips processing line process

You can see from the video that the machine in the large potato chips production line has been replaced with an automatic high-volume machine.

- The blanching machine and frying machine have been replaced with mesh belt continuous machines. The mesh belt fryer can control the frying time by controlling the speed of potato chip transportation. The machine controls the frying time and temperature by the PLC display screen. And the machine also has the features of an automatic lifting mesh belt and automatic cleaning.

- The octagonal flavoring machine is replaced with a rotarty drum seasoning machine in the large line. It can realize the continuity of seasoning while realizing automatic feeding.

- For packaging, a four-head or ten-head scale is usually used to achieve large-volume automatic packaging instead of the potato chips packaging machine above.

Semi-automatic potato chips plants VS Full-automatic potato chips production lines

Similarities

- All potato chip processing machines in the line adopt all 304 stainless steel, which is safe, hygienic, and corrosion-resistant.

- All potato chip machines have many different models, so they adapt to the needs of different customers.

- The fryer and blanching machine in the large and small potato chip lines have electric heating, air heating, and other heating methods.

- Both potato chip production lines can produce potato chips of different shapes and sizes by changing the blade of the slicing machine.

Differences

- Small-scale and large-scale production lines have different outputs. The output of the small-scale production line is between 50-300kg/h, and the output of a large-scale is between 300kg/h-2t/h.

- All machines of the large potato chips production line can be customized according to customer requirements.

- It has various differences between the two lines for labor, site area, budget, and energy consumption.

- The semi-automatic potato chip production line has a high degree of flexibility, and it can be replaced by the same function machine. Therefore, small potato chips manufacturers may purchase different chips machines. The large potato chip plant does not have so much flexibility.

- It is recommended that the workshop area required by the semi-automatic potato chip line should be less than 200 square meters. (about 50 square meters for 50kg/h, about 100 square meters for 100kg/h, and about 200 square meters for 200kg/h). The fully automatic potato chip production line generally requires a plant area of more than 500 square meters.

Advantages of the potato chips processing line

- The potato chips production line has different output, which meets the requirements of large, medium, and small potato chip manufacturers

- All chips machines are made of all 304 food-grade stainless steel, which has the characteristics of high efficiency, energy-saving, safety, and health.

- 土豆片生产线具有连续工作的特点,可以实现从原料到成品的整个工艺流程。

- 它不仅适用于土豆片的生产,还能满足甘薯片、木薯片等多种产品的生产需求。它可以实现一机多用的需求。

- 该生产线具有高效率和低投入成本,是土豆片制造商投资生产土豆片的最佳选择。

What is the potato chips production line price?

对于大多数人来说,土豆片加工线的价格是一个关注点。因为土豆片生产线具有多种不同的产量。不同容量的生产线具有不同的成本。此外,客户可能还会有其他需求或购买其他配件。因此,影响土豆片生产线价格的因素多样。

Parameters of automatic potato chips production line

| 项目 | Parameter |

| 提升输送机 | 型号:TZ-11 功率:0.55kw 电压:380V/50Hz 尺寸:1500*800*1600mm 重量:160kg 材质:全SUS 304 该机器可以手动调节速度,节省时间和能源。 |

| 螺旋刷洗机 | Model: TZ-2000 功率:3.37kw 电压:380V/50Hz 尺寸:2800*1000*1400mm 重量:450kg 材质:全SUS 304 机器内部有毛辊,可以快速擦拭土豆皮。还有螺旋用于抛光土豆。 |

| 拣选输送机 | 型号:TZ-2500 电压:380V/50Hz,三相 Moč: 0,75 kW 重量:300kg 尺寸:4000*700*900mm |

| 水桶提升机 | 型号:TZ-1500 Moč: 0,75 kW 电压:380V/50Hz 重量:330kg 尺寸:2000*950*1600mm 材质:304不锈钢 |

| 切片机 | 型号:TZ-1000-1 尺寸:1000*600*1500mm 片厚:2mm 材质:刀片采用高速不锈钢工具钢,转盘采用优质铝镁合金,其余部分采用304不锈钢 |

| 泡沫清洗机 | 型号:TZ-3000 长度:3m 带宽:800mm 尺寸:3000*1200*1300mm 重量:300kg 材质:304不锈钢 |

| Mashiinka blanching | 型号:TZ-3500 尺寸:3000*1100*1300mm 带宽:800mm 加热方式:电加热 重量:300kg 带有两个提升装置的漂烫机 |

| 脱水机 | Model: TZ-800 功率:0.5kw 电压:380V/50Hz 尺寸:1800*1000*900mm 材质:304不锈钢 |

| 风冷机 | 型号:TZ-3000-1 尺寸:3000*1200*1600mm 重量:400kg 功率:7.5kw 风扇: 6 Ballaca suunka: 800mm |

| 提升输送机 | 型号:TZ-120 Effekt: 0,75kw 电压:380V/50Hz Teža: 180 kg 尺寸:1500*800*1300mm 材质:304不锈钢 |

| 油炸机 | 型号:TZ-3500 尺寸:3500*1200*2400mm 带宽:800mm 重量:1200kg 加热方式:电加热 带有两个提升装置的油炸机 |

| 油箱 | 油泵电机功率:1.5KW/380V/50Hz 尺寸:1400*1300*1850mm 材质:304不锈钢 油储存罐配有加热功能,带过滤器,厚度为3mm,带绝缘层。 |

| 油过滤器 | 粗滤器罐直径:300mm 细滤器罐尺寸:450mm 循环泵:1.5kw |

| 去油机 | Model: TZ-800 功率:0.5kw 电压:380V/50Hz 尺寸:1800*1000*900mm 材质:304不锈钢 |

| 风冷机 | 型号:TZ-3000-1 尺寸:3000*1200*1600mm 重量:400kg 功率:7.5kw 风扇:6 带宽:800mm |

| 提升输送机 | 型号:TZ-120 Moč: 0,75 kW 电压:380V/50Hz Teža: 180 kg 尺寸:1500*800*1300mm 材质:304不锈钢 |

| 调味机 | Model: TZ-2400 尺寸:2400*1000*1600mm 功率:1.5kw 电压:380V,50Hz,三相 |

| 10头全自动包装机 | A.送料输送机 容量:3-6m³/h 电压:380V 重量:500kg B.TZ-720立式自动包装机 袋长:100-400mm(L) 袋宽:180-350mm(W) 最大卷膜宽度:720mm 包装速度:5-50袋/分钟 测量范围:6000ml(最大) 气体消耗:0.65Mpa 气体消耗:0.4m³/分钟 电压:220VAC/50Hz 功率:5kw 尺寸:1780*1350*1950mm C.10桶多头称重机 最大称重:1000g 单次称重范围:10-1000g Natančnost tehtanja: ±0,3~1,5 g 称重速度:最大3000cc 控制单元:8.4英寸触摸屏 D.平台防滑台面,周围有护栏,实用且安全。 E.成品输送线 包装重量:少于2.5kg |

以上显示了我们土豆片加工线的通用技术参数。作为土豆片机制造商,我们提供不同容量的自动和半自动机器,以满足客户需求。

也提供配套设备。通常,机器尺寸越大,产量越高。例如,清洗和去皮机的 roller 长度不同。对于特殊需求,我们可以定制机器。

以下是不同产量的土豆片加工厂

FAQ about potato chips production solutions

How many potato chips can be made from 1kg of potatoes?

0.3kg potato chips.

How long should I wash potatoes when using a washing machine?

This is based on the freshness of the potatoes you use. If you use fresh potatoes, they generally need 1-2 minutes; for comparison potatoes, they need 5-6 minutes.

Do I need to add anything when blanching? How long is the blanching time?

You can add 1kg of edible salt, 0.5kg of sodium pyrophosphate, 0.5kg of citric acid, and 1kg of glucose powder. The blanching time is generally 2 minutes. This machine has a timing function.

How long does it take to fry? What is the frying temperature?

General frying 5min, oil temperature at 160-180℃.

Can the temperature of the blanching machine and fryer be adjusted?

Adjustable.

What is the machine material for the potato chips making machine?

All 304 stainless steel.

Can you customize a plan for me according to my plant area?

Yes, we will supply complete potato chip solutions from A to Z based on your processing requirements.

What is the general delivery time of your machines?

If all chip machines are in stock, it will take about 10 days, if not, generally need about 15-30 days.