Diese 200kg/h Gefrorene Pommes-frites-Verarbeitungsanlage ist eine halbautomatische Linie mit relativ geringem Output, geeignet für kleine französische Pommes-Frites-Produktionsstätten. Die Produktionskapazität wird allgemein mit 50kg/h-300kg/h angegeben und kann bestimmte Kundengruppen in kleinen Snack-Food-Fabriken, Lebensmittelgeschäften oder Restaurants bedienen.

Die mittlere Größe der gefrorenen Pommes-frites-Verarbeitungsanlage ist einfach und sicher zu bedienen, platzsparend und zeichnet sich durch moderate Investitionen und schnelle Amortisation aus. Wir bieten auch andere Arten von Pommes-frites-Verarbeitungsanlagen mit mittlerer oder großer Kapazität an.

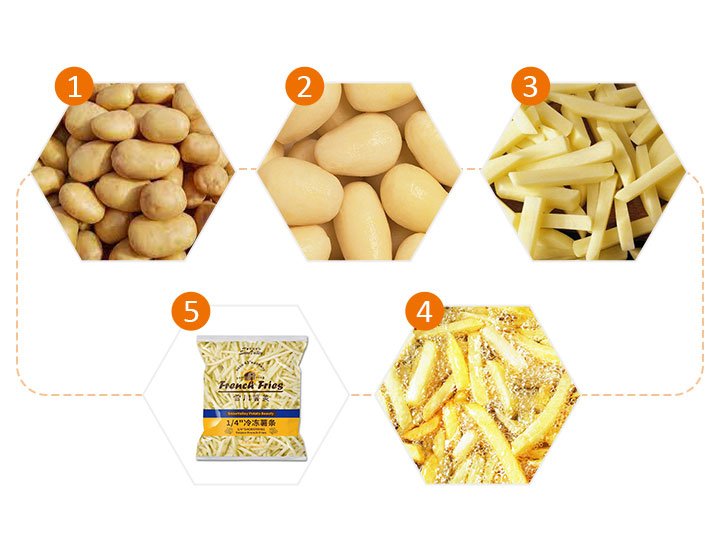

Der Herstellungsprozess der gefrorenen Pommes-frites-Verarbeitungsanlage

- Kartoffelwaschen und Schälen

- Pommes Frites Schneidemaschine

- Blanchieren der Kartoffeln

- Wasser-Trocknung

- Schnelles Frittieren

- Öltrocknung

- Schnellgefrieren

- Verpackungsmaschine

Verkauf der Pommes-frites-Produktionlinie

Kleine französische Pommes-Frites-Produktionlinie umfasst hauptsächlich die Kartoffelwasch- und Schälenmaschine, Pommes-frites-Schneidemaschine, Kartoffelblanchiermaschine, Trocknungsmaschine, Pommes-frites-Frittiermaschine, Öltrocknungsmaschine und Schnellgefriermaschine. Nachfolgend eine allgemeine Einführung zu einzelnen Maschinen.

Kartoffelwasch- und Schälenmaschine

Die Kartoffelwasch- und Schälenmaschine verfügt sowohl über Wasch- als auch Schälfunktionen. Die Bürstenwalzen können die Kartoffeln schrubben, um die Schale zu entfernen, ohne die Kartoffeln zu beschädigen, während die Sprühvorrichtung Verunreinigungen auf der Oberfläche des Materials abwäscht.

Pommes-frites-Schneidemaschine

Die Pommes-frites-Schneidemaschine kann die Kartoffeln in Streifen oder Scheiben schneiden. Die Scheiben oder Streifen sind einheitlich in der Größe. Es ist einfach, die Messer auf die erwarteten Materialgrößen einzustellen.

Kartoffelblanchiermaschine

Um die Stärke aus den Kartoffeln zu entfernen, ist es notwendig, die Kartoffelstreifen zu blanchieren. Die Kartoffelblanchiermaschine kann mit Gas oder Strom beheizt werden und verfügt über eine kontrollierbare Temperatur, um Überhitzung zu vermeiden. Die Blanchiertemperatur liegt bei 80-100℃.

Wasser-Trocknungsmaschine

Die Wasser-Trocknungsmaschine entfernt überschüssiges Wasser im vorherigen Verarbeitungsschritt durch Zentrifugalkraft. Dieser Trocknungsschritt kann später die Frittierzeit verkürzen und den Geschmack der Pommes-frites verbessern.

Pommes-frites-Frittiermaschine

Die Pommes-frites-Frittiermaschine kann die Kartoffelstreifen effizient mit Gas- oder Stromheizung frittieren. Die Frittierungstemperatur erreicht etwa 160-180℃, und das schnelle Frittieren dauert etwa 40s bis 60s. Die Frittiermaschine kann die Form von Pommes-frites in der Kleine französische Pommes-Frites-Linie bilden und ist für die weitere Verarbeitung bereit.

Öldryer-Maschine

Das Entfernen von überschüssigem Öl auf der Oberfläche der Pommes-frites kann helfen, den fettigen Geschmack zu vermeiden. Die Öltrocknungsmaschine kann die Pommes-frites effizient trocknen und dabei wenig Energie verbrauchen. Sie basiert auf dem Prinzip der Zentrifugalkraft.

Schnellgefriermaschine

Die Gefriermaschine verfügt über einen Kupferroterevaporator mit ausgeglichener Temperatur. Sie kann die Lebensmittel über einen längeren Zeitraum frisch halten. Das Temperaturregelsystem ermöglicht eine präzise Temperaturkontrolle.

Pommes-frites-Verpackungsmaschine

Im letzten Schritt in der Gefrorene Pommes-frites-Verarbeitungsanlage und der Pommes-frites-Linie ist es in der Regel notwendig, eine Gefrorene Pommes-frites-Verpackungsmaschine zu verwenden, um Kartoffelchips zu verpacken. Nach dem Verpacken ist der Transport und das Tragen sehr bequem. Allgemein verwendete Verpackungsmaschinen für Kartoffelchips auf dem Markt sind Vakuumverpackungsmaschinen und Beutelverpackungsmaschinen.

Für die Verpackung von gefrorenen Pommes-frites können wir Vakuumverpackung und normale Beutelverpackung wählen. Besonders bei Beutelverpackungen kann unsere Pommes-frites-Verpackungsmaschine auf die gewünschten Packungsgrößen, Packungsgewichte und -geschwindigkeiten eingestellt werden.

Spezifikation der gefrorenen Pommes-frites-Verarbeitungsanlage

| Maschinenname | 50kg/h | 100kg/h | 200kg/h | 300kg/h |

| Kartoffelwasch- und Schälenmaschine | Abmessungen: 2200 * 850 * 900 mm Länge der Walze: 1200 mm Leistung: 2,95kw | Abmessungen: 2500 * 850 * 900 mm Länge der Walze: 1500mm Leistung: 2,95kw | Abmessungen: 2800 * 850 * 900 mm Länge der Walze: 1800mm Leistung: 4kw | Abmessungen: 3000 * 850 * 900 mm Länge der Walze: 2000mm Leistung: 4kw |

| Pommes-frites-Schneidemaschine | Abmessungen: 850 * 850 * 1000 mm Leistung: 0,75 kW Schnittgröße: 3-8 mm | Abmessungen: 850 * 850 * 1000mm Leistung: 0,75 kW Schnittgröße: 3-8 mm | Abmessungen: 850 * 850 * 1000mm Leistung: 0,75 kW Schnittgröße: 3-8 mm | Abmessungen: 850 * 850 * 1000 mm Leistung: 0,75 kW Schnittgröße: 3-8 mm |

| Kartoffelblanchiermaschine | Abmessungen: 2500 * 950 * 1250mm Gitterbandbreite: 600mm Elektrische Heizleistung: 48 kw | Abmessungen: 3000 * 1150 * 1250 mm Gitterbandbreite: 800mm Elektrische Heizleistung: 60 kw | Abmessungen: 4000 * 1150 * 1250mm Gitterbandbreite: 800mm Elektrische Heizleistung: 90 kw | Abmessungen: 6000 * 1150 * 1250mm Gitterbandbreite: 800mm Elektrische Heizleistung: 170 kw |

| Wasser-Trocknungsmaschine | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw |

| Pommes-Frites-Fritteuse | Abmessungen: 2500 * 1200 * 1550 mm Gitterbandbreite: 600mm Elektrische Heizleistung: 48kw | Abmessungen: 3000 * 1150 * 1550 mm Gitterbandbreite: 800mm Elektrische Heizleistung: 60 kw | Abmessungen: 4000 * 1150 * 1550 mm Gitterbandbreite: 800mm Elektrische Heizleistung: 90 kw | Abmessungen: 6000 * 1150 * 1550 mm Gitterbandbreite: 800mm Elektrische Heizleistung: 120 kw |

| Öltrocknungsmaschine | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw | Größe: 1000*500*700mm Gewicht: 200kg Leistung: 1,5kw |

| Schnellgefrieren | Länge: 7100mm Temperatur des Gefrierzentrums: – 18 ° Material: 304SS | Länge: 7100mm Temperatur des Gefrierzentrums: – 18 ° Material: 304SS | Länge: 9100mm Temperatur des Gefrierzentrums: – 18 ° Material: 304SS | Länge: 11000mm Temperatur des Gefrierzentrums: – 18 ° Material: 304SS |