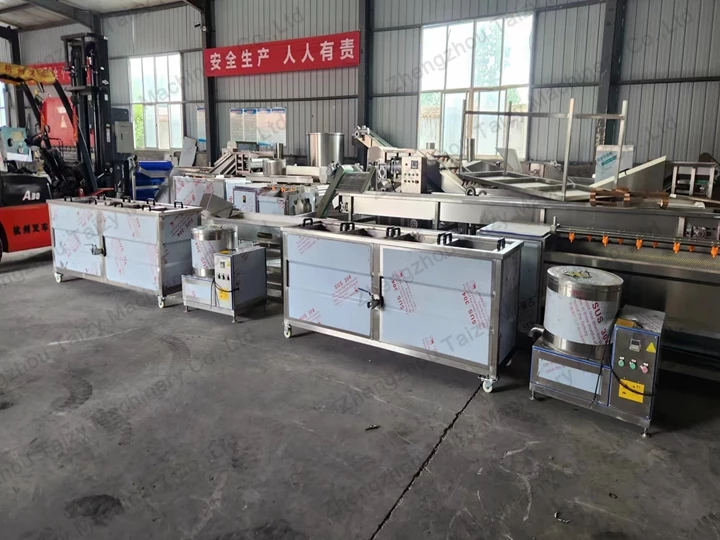

This 200kg/h frozen french fries processing line is a semi-automatic frozen fries line with relatively small outputs, suitable for small-scale French fries processing plants. The production capacity is generally referred to as 50kg/h-300kg/h, which can meet certain groups of customers in small-sized snack food factories, food stores, or restaurants.

The medium size frozen French fries production line is easy and safe to operate, space-saving, and has the feature of moderate investment and fast return. We also offer other types of french fries processing lines with medium or large outputs.

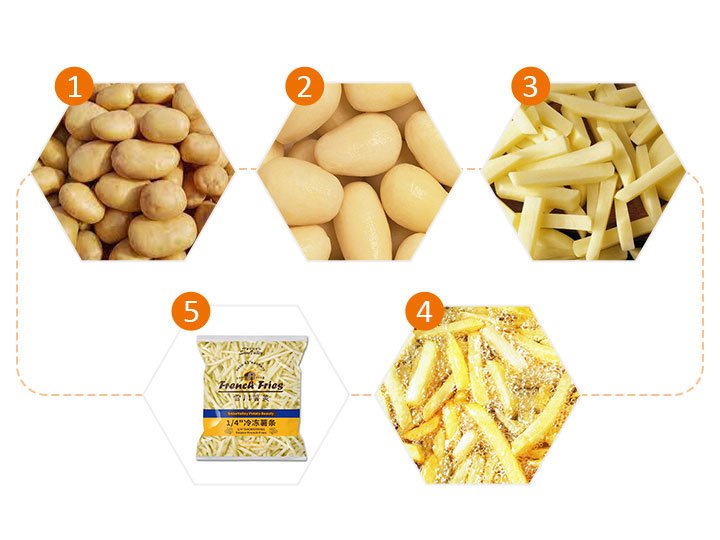

The production process of frozen french fries processing line

- Potato washing and peeling

- French fries cutting

- Potato blanching

- Water drying

- Quick frying

- Oil drying

- Quick freezing

- Packing machine

French fries production line for sale

Small-scale French fries production line mainly includes the potato washing and peeling machine, french fries cutter machine, potato blanching machine, drying machine, french fries frying machine, oil dryer machine, and quick freezer. The following is a general introduction to single machines.

Potato washing and peeling machine

The potato washing and peeling machine have both washing and peeling functions. The brush rollers can scrub the potatoes to remove the skins without damage to the potatoes, while the spraying device washes away the impurities on the material surface.

French fries cutter machine

The French fries cutter machine can cut the potatoes into strips or slices. The slices or strips are in uniform size. It is easy to adjust the cutters for expected material sizes.

Potato blanching machine

To remove the starch from potatoes, it is needy to blanch the potato strips. The potato blanching machine can be heated by gas or electricity, with a controllable temperature to avoid overheating. The blanching temperature reaches 80-100℃.

Water dryer machine

The water dryer machine is to remove additional water in the previous processing step by using centrifugal force. The step of water drying can help save frying time later and improve the taste of french fries.

French fries frying machine

The French fries frying machine can efficiently fry the potato strips with a gas or electricity heating source. The frying temperature reaches about 160-180℃ and the quick frying takes about 40s to 60s. The frying machine can form the shape of french fries in the Small-scale French fries production line and is ready for further processing.

Oil dryer machine

Removing extra oil on the french fry’s surface can help avoid the greasy taste of food. The oil dryer machine can efficiently dry the oil of french fries with low energy consumption. It follows the principle of centrifugal force.

Quick freezer machine

The freezer machine has a copper tube evaporator with a balanced temperature in it. It can keep the food fresh for a quite long time. The temperature control system can realize accurate temperature.

French fries packaging machine

In the last step in the frozen french fries processing line and French fries line, it is usually necessary to use a frozen french fries packaging machine to package potato chips. After using the packaging machine to pack, it is very convenient to transport and carry. Generally speaking, the potato chip packaging machines frequently used in the market include vacuum packaging machines and bucket packaging machines.

For frozen french fries packaging, we can choose vacuum packing and normal bag packing. Especially for bag packing, our french fries packaging machine can be set for the packing size, packing weight, and packing speed based on your needs.

Specification of frozen french fries processing line

| Machine name | 50kg/h | 100kg/h | 200kg/h | 300kg/h |

| potato washing and peeling machine | Size: 2200 * 850 * 900 mm Length of roller: 1200mm Power: 2.95kw | Size: 2500 * 850 * 900 mm Length of roller: 1500mm Power: 2.95kw | Size: 2800 * 850 * 900 mm Length of roller: 1800mm Power: 4kw | Size: 3000 * 850 * 900 mm Length of roller: 2000mm Power: 4kw |

| french fries cutter machine | Size: 850 * 850 * 1000 mm Power: 0.75kw Cutting strip size: 3-8mm | Size: 850 * 850 * 1000mm Power: 0.75kw Cutting strip size: 3-8mm | Size: 850 * 850 * 1000mm Power: 0.75kw Cutting strip size: 3-8mm | Size: 850 * 850 * 1000 mm Power: 0.75kw Cutting strip size: 3-8mm |

| potato blanching machine | Size: 2500 * 950 * 1250mm Mesh belt width: 600mm Electric heating power: 48 kw | Size: 3000 * 1150 * 1250 mm Mesh belt width: 800mm Electric heating power: 60 kw | Size: 4000 * 1150 * 1250mm Mesh belt width: 800mm Electric heating power: 90 kw | Size: 6000 * 1150 * 1250mm Mesh belt width: 800mm Electric heating power: 170 kw |

| water drying machine | size:1000*500*700mm weight:200kg power:1.5kw | size:1000*500*700mm weight:200kg power:1.5kw | size:1000*500*700mm weight:200kg power:1.5kw | size:1000*500*700mm weight:200kg power:1.5kw |

| french fries frying machine | Size: 2500 * 1200 * 1550 mm Mesh belt width: 600mm Electric heating power: 48kw | Size: 3000 * 1150 * 1550 mm Mesh belt width: 800mm Electric heating power: 60 kw | Size: 4000 * 1150 * 1550 mm Mesh belt width: 800mm Electric heating power: 90 kw | Size: 6000 * 1150 * 1550 mm Mesh belt width: 800mm Electric heating power: 120 kw |

| oil dryer machine | size:1000*500*700mm weight:200kg power:1.5kw | size:1000*500*700mm weight:200kg power:1.5kw | size:1000*500*700mm weight:200kg power:1.5kw | size:1000*500*700mm weight:200kg power:1.5kw |

| quick freezer | length: 7100mm Freezing center temperature: – 18 ° Material: 304SS | Length: 7100mm Freezing center temperature: – 18 ° Material: 304SS | Length: 9100mm Freezing center temperature: – 18 ° Material: 304SS | Length: 11000mm Freezing center temperature: – 18 ° Material: 304SS |