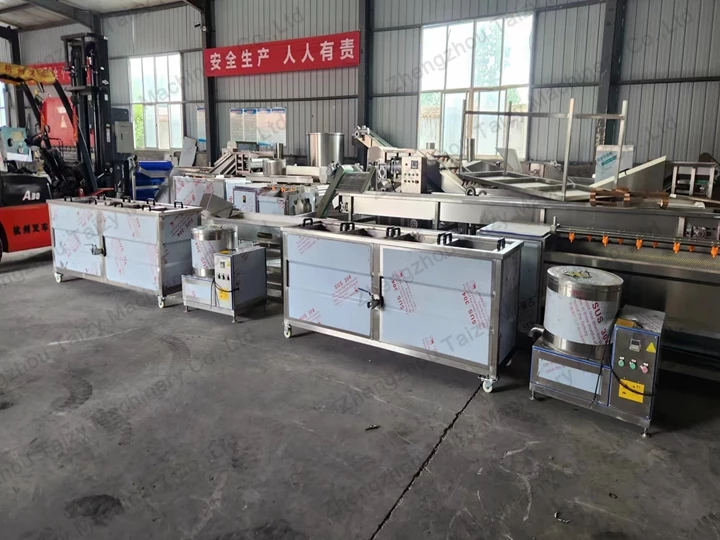

The taro peeling machine (also called a potato washing peeling machine) is widely used for cleaning and peeling taro, potatoes, and other round and oval fruits and vegetables. The taro peeler machine not only has an extensive cleaning and peeling volume but also has high efficiency and low energy consumption. The body of the automatic taro peeling machine is made of stainless steel, with fine quality, beautiful appearance, advanced design, and high technical content. The taro cleaner can automatically rotate and discharge materials. The transmission system of this machine adopts the transmission form of a belt, sprocket, and so on. It is mainly composed of motor, transmission, 8-12 rollers, etc. There are Model-1200, Model-1500, Model-2000, and other types. The automatic taro peeler machine can be a good helper for the fruit and vegetable processing business.

Advantages of taro peeling machine

- All parts of the taro peeler machine in contact with food are made of 304 stainless steel that meets food hygiene requirements to ensure long-term work without rust, corrosion, toxicity, and harm.

- The taro cleaner adopts a food-grade belt and food-grade brush for conveying and cleaning and uses rotating brushes with high-pressure spray, which has a good cleaning effect and can thoroughly clean the stains on the surface of fruits and vegetables.

- The brush roller is not easy to deform, and the hairbrush is made of nylon rope, which is durable.

- The cleaning volume is large, the scrubbing is cleaner, the raw materials are not damaged, and the product is smoother and brighter. The output of the automatic taro peeling machine can reach 500-2000kg/h.

- Low energy consumption, small size, beautiful appearance, and convenient operation.

What is the use of the taro peeler machine?

The automatic taro peeling machine is widely used in the cleaning and peeling of round and oval fruits and vegetables such as potato, potato, sweet potato, ginger, carrot, kiwi, and other root vegetables.

This taro peeling machine can be cleaned separately, or it can be cleaned and peeled at the same time. The hardness of the brush determines whether the raw material is peeled or not.

How to clean taro or peel taro skin?

The brush taro peeling machine is divided into two types: soft brush and hard brush, and the cleaning method is selected according to actual needs. A soft brush is used for cleaning. A stiff brush can be cleaned and peeled. The working principle of the taro cleaner is to use the rotation of the brush to perform friction cleaning on the materials to be cleaned. The soft brush is mainly for cleaning materials that are easily damaged, which can well protect the surface of the material from damage and ensure its integrity of the material. For the material that needs to be cleaned and peeled, a brush made of hard nylon wire is used to clean the material. The time for material cleaning can be set as required.

Working process of automatic taro peeling machine

After putting the raw materials in the machine, the taro cleaner and peeler uses the rotating friction of the brushes to clean the raw materials. The friction cleaning only cleans the skin of the raw materials without damaging the meat of the raw materials. Hard brush friction can remove the skin of the raw material. The equipment is designed in two forms: forward rotation and reverse rotation for rotation and discharging functions respectively. After cleaning, the material can be rotated and discharged by the rotation of the brush.

The taro peeling machine is equipped with a ring water pump and a filter water tank, which realizes cleaning and recycling, saves water, and supplements, and replaces new water according to the actual production situation. The motor of the conveyor belt can realize the function of adjusting the speed change. The cleaned vegetables are conveyed through the net chain, and the materials are automatically fed and discharged. Adjust the conveying speed of the conveyor belt according to the production needs. Thus, the machine is simple to operate and maintain, with high work efficiency.