The semi-automatic frozen french fries processing machine is suitable for the processing of medium-capacity French fries, applicable to restaurants, canteens, cafes, or snack processing plants.

This frozen french fries production line has the advantages of moderate one-time investment, low energy consumption, multiple application, flexible production, convenient use, and maintenance, etc.

It can also be used for processing sweet potato chips, finger chips, etc. The whole set of fries processing machinery consists of a cleaning and peeling machine, french fries cutting machine, blanching machine, water dryer, french fries frying machine, de-oiling machine, quick freezer, packaging machine, and other supportive equipment.

We also offer small-scale french fries production lines and fully automatic french fries production lines with various outputs.

Semi-auto French fries production line processing flow

- Washing and peeling: potatoes are cleaned and peeled by the potato cleaning and peeling machine. It can efficiently realize thorough washing and peeling without damage to the potatoes.

- Chip cutting: potatoes are quickly cut into chips of corresponding specifications by high-speed french fries cutting machine.

- Blanching: the blanching machine is used to passivate the oxidase in French fries and prevent color deterioration.

- Water drying: after blanching, the French fries need to remove excess water so that it will not affect the next processing step of frying.

- Frying: quickly fry French fries for 40-60 seconds to shape them to become semi-finished products. The frying temperature is about 160-180 degrees.

- De-oiling: after the frying step, remove the excess oil through the oil dryer machine to avoid the greasy taste.

- Quick freezing: fried French fries need to be frozen quickly, which takes 15-45 minutes. Freezing does not affect the flavor of french fries and it is a necessary step to keep the taste.

- Packaging: Packaging and storing the frozen French fries for further processing. The packaging machine can weigh the materials and pack them with high efficiency.

Frozen french fries production line video

Parameter of frozen french fries processing machinery

| Items | Machine picture | 100kg/h |

| Potato Washing And Peeling Machine |  | Size: 3600*850*900 mm Length of roller: 2600mm Power: 5.5kw Material:304SS |

| French Fries Cutter Machine |  | Size: 850 * 850 * 1000 mm Power: 0.75kw Cutting strip size: 3-8mm Material:304SS |

| Potato Blanching Machine |  | Size: 8000*1350*1250mm Mesh belt width: 1000mm Electric heating power: 240kw Material:304SS |

| Water Dryer Machine |  | size:1200*700*750mm weight:420kg power:2.2kw |

| French Fries Fryer Machine |  | Size:10000*1450*1550mm Mesh belt width: 1000mm Electric heating power: 320kw Material:304SS |

| Oil Dryer Machine |  | size:1200*700*750mm weight:420kg power:2.2kw |

| Quick Freezer |  | Length: 15000mm Freezing center temperature: – 18 ° Material: 304SS |

| French Fries Packaging Machine |  | Maximum weight: 1000g Single weighing range:10-1000g Weighing speed:60 times/min |

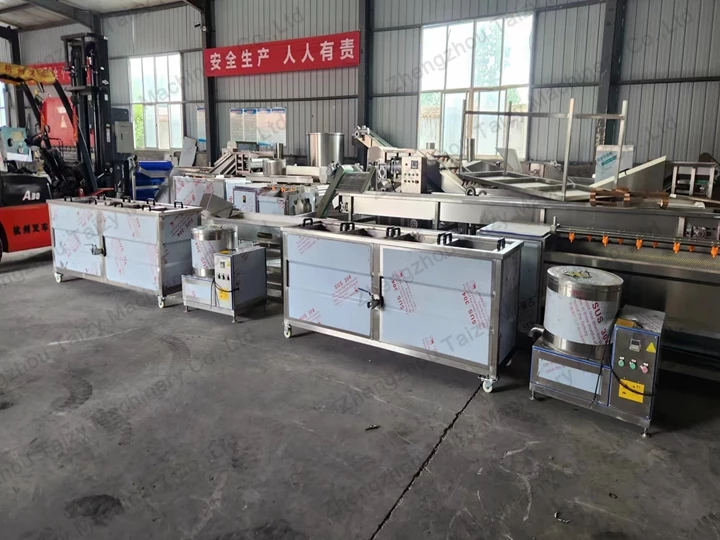

Taizy factory with frozen french fries processing machines display

Welcome to visit Taizy factory for french fries equipment solutions. If you have any requirements about the frozen french fries processing machine, welcome to contact us directly. We can customize the special production plans based on your budget and actual requirements.