Η γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας περιλαμβάνει επαγγελματικά σχεδιασμένα μηχανήματα για την κατασκευή κατεψυγμένων τηγανητών πατάτας από φρέσκες πατάτες. Η διαδικασία παραγωγής περιλαμβάνει κυρίως πλύσιμο και peeling πατάτας, κοπή, λεύκανση, ξήρανση, τηγάνισμα, αποξήρανση λαδιού, κατάψυξη και συσκευασία. Η γραμμή παραγωγής χαρακτηρίζεται από υψηλή αποδοτικότητα, ποιοτικά προϊόντα, διάφορες αποδόσεις, οικονομική αποδοτικότητα, εύκολη λειτουργία, κ.λπ.

Ανάλογα με την παραγωγή, οι εγκαταστάσεις επεξεργασίας τηγανητών πατάτας διακρίνονται σε μικρής κλίμακας ημι-αυτόματες και πλήρως αυτόματες. Η γενική παραγωγή της μικρής γραμμής είναι 50kg/h, 100kg/h, 200kg/h, και 300kg/h. Το εύρος παραγωγής της πλήρους αυτόματης γραμμής είναι 300kg/h-2t/h.

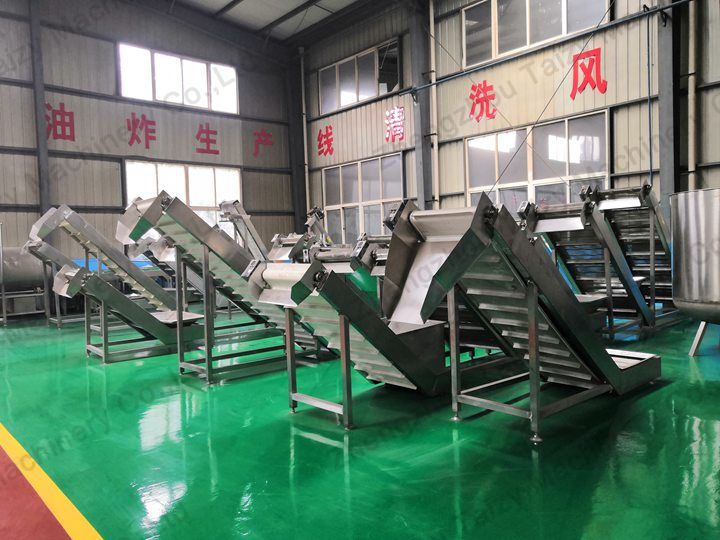

Ως κατασκευαστής γραμμών παραγωγής τηγανητών πατάτας, προσφέρουμε ολόκληρα σετ μηχανημάτων παραγωγής, καθώς και μεμονωμένα μηχανήματα και υποστηρικτικό εξοπλισμό, και παρέχουμε επίσης προσαρμοσμένα μηχανήματα για να ταιριάζουν στις ανάγκες του πελάτη. Το εργοστάσιο επεξεργασίας τηγανητών πατάτας είναι κατάλληλο για εργοστάσια σνακ, εστιατόρια, ξενοδοχεία, εργαστήρια τροφίμων, καταστήματα fast food, και άλλα.

Επισκόπηση γραμμής παραγωγής κατεψυγμένων τηγανητών πατάτας

Εφαρμογή: Κυρίως χρησιμοποιείται για την παραγωγή κατεψυγμένων τηγανητών πατάτας, πατατάκια, δαχτυλίδια πατάτας, τηγανητές πατάτες

Παραγωγή: Η γραμμή παραγωγής τηγανητών πατάτας διαθέτει ημι-αυτόματες και πλήρως αυτόματες γραμμές παραγωγής. Η μικρής κλίμακας γραμμή παράγει 50-300kg/h, και η πλήρως αυτόματη γραμμή 300-2000kg/h.

Προσαρμοσμένο ή όχι: ναι

Τρόπος θέρμανσης: ηλεκτρική θέρμανση, αερίου

Δημοφιλείς περιοχές: Τουρκία, Γερμανία, Ιταλία, Αλγερία, Σαουδική Αραβία, Ιράκ, και άλλες περιοχές

Διαδικασία παραγωγής: Ημι-αυτόματη και πλήρως αυτόματη γραμμή παραγωγής. Η μικρής κλίμακας γραμμή παράγει 50kg/h, 100kg/h, 200kg/h, και 300kg/h. Η πλήρης αυτόματη γραμμή παράγει 300kg/h-2t/h.

Βίντεο επεξεργασίας γραμμής παραγωγής κατεψυγμένων πατατών 3D

Διαδικασία γραμμής παραγωγής ημι-αυτόματων κατεψυγμένων τηγανητών πατάτας

- Πλύσιμο & peeling πατάτας

μέγεθος: 1600*850*800 mm

ισχύς: 0.75kw

χωρητικότητα: 200kg/h

βάρος: 280kg

Το μηχάνημα πλύσης και peeling πατάτας διαθέτει λειτουργίες πλυσίματος και peeling. Οι βούρτσες μέσα στη μηχανή μπορούν να απομακρύνουν πλήρως το περίβλημα της πατάτας, χωρίς να την καταστρέφουν. Ο χρόνος πλυσίματος είναι περίπου 5-6 λεπτά.

- Κοπή τηγανητών πατάτας

Μέγεθος: 950*800*1600mm

κοπή: 6*6mm έως 15*15mm (μπορεί να προσαρμοστεί)

ισχύς: 1.1kw

χωρητικότητα: 600-800kg/h

Αυτό το μηχάνημα κοπής τηγανητών πατάτας προορίζεται για το κόψιμο πατάτας σε λωρίδες. Οι πατάτες πρώτα κόβονται σε φέτες και στη συνέχεια σε λωρίδες. Το μέγεθος της λωρίδας πατάτας είναι ρυθμιζόμενο, επιτυγχάνεται αλλάζοντας το κενό μεταξύ των λεπίδων. Συνήθως, οι περισσότεροι πελάτες προτιμούν το μέγεθος 8*8mm και 9*9mm, και η εμβέλειά του είναι από 6*6mm έως 15*15mm. Οι λεπίδες είναι ευάλωτα ανταλλακτικά, οπότε συνιστώ έντονα να αγοράσετε επιπλέον λεπίδες.

- Λεύκανση

μέγεθος: 1200*700*950mm

ισχύς: 12kw

βάρος: 120kg

χωρητικότητα: 100 kg/h

Το μηχάνημα λεύκανσης προορίζεται για την αφαίρεση του άμυλου από τις λωρίδες πατάτας, ώστε οι τελικές τηγανητές πατάτες να έχουν λαμπερό χρώμα και καλύτερη γεύση. Ο τρόπος θέρμανσης περιλαμβάνει ηλεκτρική θέρμανση και αερίου, και μπορείτε να επιλέξετε όποιον θέλετε με βάση την κατάσταση σας. Η θερμοκρασία λεύκανσης είναι 80-100℃. Διαθέτει αυτόματο σύστημα ελέγχου θερμοκρασίας, και η θερμοκρασία είναι ρυθμιζόμενη.

- Αποξήρανση

μέγεθος: 1100*500*850mm ισχύς: 1.5kw βάρος: 150kg χωρητικότητα: 200kg/h Το μηχάνημα απομάκρυνσης νερού μπορεί να αποτρέψει την επιφάνεια των λευκανθέντων πατάτας από το να περιέχει πολύ νερό και να πιτσιλίζει. Χρησιμοποιεί την αρχή της φυγόκεντρης αποξήρανσης, και ο χρόνος αποξήρανσης μπορεί να προγραμματιστεί. Γενικά, ο χρόνος λεύκανσης είναι 1 έως 2 λεπτά. Επιπλέον, συχνά χρησιμοποιείται στη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας και μηχάνημα αεροξήρανσης, που μπορεί συνεχώς να αφαιρεί το νερό από την επιφάνεια των λωρίδων πατάτας με ισχυρό αέρα.

- Τηγάνισμα τηγανητών πατάτας

μέγεθος: 1200*700*950mm

ισχύς: 24kw

βάρος: 120kg

χωρητικότητα: 100 kg/h

Το μηχάνημα τηγανίσματος προορίζεται για το κόψιμο πατάτας σε λωρίδες. Οι πατάτες πρώτα κόβονται σε φέτες και στη συνέχεια σε λωρίδες. Το μέγεθος της λωρίδας πατάτας είναι ρυθμιζόμενο, επιτυγχάνεται αλλάζοντας το κενό μεταξύ των λεπίδων. Συνήθως, οι περισσότεροι πελάτες προτιμούν το μέγεθος 8*8mm και 9*9mm, και η εμβέλειά του είναι από 6*6mm έως 15*15mm. Οι λεπίδες είναι ευάλωτα ανταλλακτικά, οπότε συνιστώ έντονα να αγοράσετε επιπλέον λεπίδες.

- Αφαίρεση λαδιού από τηγανητές πατάτες

μέγεθος: 1100*500*850mm

ισχύς: 1.5kw

βάρος: 350kg

χωρητικότητα: 200kg/h

Μετά το τηγάνισμα, πρέπει να χρησιμοποιήσετε μηχάνημα απομάκρυνσης λαδιού για να αφαιρέσετε το πολύ λάδι στην επιφάνεια των τηγανητών λωρίδων πατάτας. Το μηχάνημα απομάκρυνσης λαδιού είναι ίδιο με το μηχάνημα απομάκρυνσης νερού.

- Κατεψυγμένες τηγανητές πατάτες

Ένα γρήγορο ψυγείο προορίζεται για την κατάψυξη των τηγανητών πατάτας ώστε να μην κολλάνε μεταξύ τους κατά τη συσκευασία. Ο χρόνος κατάψυξης είναι 20-30 λεπτά, και η ελάχιστη θερμοκρασία είναι -45℃. Οι τηγανητές πατάτες που καταναλώνουμε συνήθως στα McDonald’s ξανατηγανίζονται έξω από το ψυγείο. Το μέγεθος του μηχανήματος μπορεί να προσαρμοστεί σύμφωνα με τις απαιτήσεις.

- Συσκευασία τηγανητών πατάτας

Ένα μηχάνημα συσκευασίας τηγανητών πατάτας προορίζεται για τη συσκευασία διαφόρων σνακ, με τις πολλαπλές λειτουργίες αυτόματου ζύγισης, συσκευασίας και σφράγισης. Προσφέρουμε μηχανήματα συσκευασίας πατατόchips κενού και μηχανήματα συσκευασίας πατατόchips με δέκα κάδους.

Βίντεο λειτουργίας ημι-αυτόματης μηχανής τηγανητών πατάτας

Χαρακτηριστικά μικρής κλίμακας μηχανημάτων επεξεργασίας τηγανητών πατάτας

Η μικρής κλίμακας γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας διαθέτει πολλά εξαιρετικά χαρακτηριστικά:

1. Η μηχανή καθαρισμού πατάτας στη μικρή γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας διαθέτει δύο λειτουργίες: καθαρισμό και peeling. Οι βούρτσες μέσα στη μηχανή μπορούν να απομακρύνουν πλήρως το περίβλημα της πατάτας, χωρίς να την καταστρέφουν. Ο χρόνος πλυσίματος είναι περίπου 5-6 λεπτά. Επιπλέον, μπορεί να καθαρίσει και άλλα φρούτα και λαχανικά όπως τζίντζερ, ημερομηνίες και καρότα.

2. Το μηχάνημα κοπής τηγανητών πατάτας στη ημι-αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας κατασκευάζεται με εισαγόμενα εξαρτήματα από την Ταϊβάν. Το εύρος κοπής είναι 6*6mm~15*15mm. Φυσικά, μπορούμε να προσαρμόσουμε πολλαπλές λεπίδες κοπής σύμφωνα με τις ανάγκες του πελάτη. Αλλάζοντας τη λεπίδα, μπορείτε να χρησιμοποιήσετε ένα μηχάνημα κοπής για να φτιάξετε πολλαπλά μεγέθη τηγανητών πατάτας.

3. Τόσο η μηχανή λεύκανσης όσο και η μηχανή τηγανίσματος σε αυτήν τη γραμμή παραγωγής διαθέτουν ηλεκτρική και αερίου θέρμανση. Οι ηλεκτρικές θερμαντικές σωλήνες τους αποτελούνται από σωλήνες θερμάνσεως χωρίς ραφή, και η ισχύς τους είναι χαμηλή. Η χρήση σωλήνων χωρίς ραφή μπορεί να κάνει τις μηχανές ασφαλείς και αποδοτικές.

4. Ο καταψύκτης είναι το πιο σημαντικό μηχάνημα που διακρίνει τη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας από τη γραμμή παραγωγής πατατάκια. Ο καταψύκτης μπορεί να εξοπλιστεί σύμφωνα με τις ανάγκες του πελάτη.

Μηχανή τηγανίσματος 100kg/H ημι-αυτόματη

Πλήρως αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας

Σε σύγκριση με τη ημι-αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας, η αυτόματη γραμμή αντικαθιστά τη μηχανή αυτόματης τηγανητής πατάτας. Επιπλέον, προσθέτει μηχανή επιλογής και πλυντήριο πριν από τη μηχανή λεύκανσης.

Και αυτό διακρίνει τη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας από τη γραμμή παραγωγής πατατάκια. Μπορεί επίσης να παράγει πατατάκια προσθέτοντας ή αφαιρώντας μηχανήματα στη βάση της γραμμής παραγωγής τηγανητών πατάτας.

Μηχανήματα που απαιτούνται στη πλήρη αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας

Όπως φαίνεται στον πίνακα, υπάρχει μια σειρά μηχανημάτων με τυπικές παραμέτρους στη αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας. Σε σύγκριση με μια ημι-αυτόματη γραμμή, χρησιμοποιούνται πολλαπλοί ανυψωτές, μεταφορικές ταινίες, και διαφορετικού τύπου μηχανές ξήρανσης και συσκευασίας για την επίτευξη συνεχούς παραγωγής και μείωση εργασίας. Τα κύρια μηχανήματα και ο υποστηρικτικός εξοπλισμός μπορούν να προσαρμοστούν ευέλικτα σύμφωνα με τις πραγματικές ανάγκες.

| Είδος | Εικόνα | Παραμέτρους |

| 1. ανυψωτής |  | Μοντέλο: TZ-100 Ισχύς: 0.55kw Τάση: 380v/50Hz Βάρος: 180kg Μέγεθος: 1500*800*1600mm Ταχύτητα ιμάντα: ρυθμιζόμενη Υλικό: ανοξείδωτο ατσάλι 304 |

| 2. πλύσιμο και peeling |  | Μοντέλο: TZ-2600 Ισχύς: 4,37kw Τάση: 380v/50Hz Βάρος: 480kg Μέγεθος: 3400*1000*1400mm Ρυθμιζόμενη ταχύτητα εσωτερικού κοχλία Χωρητικότητα: 2400kg/h Υλικό: ανοξείδωτο ατσάλι 304 |

| 3. μεταφορική ταινία επιλογής |  | Μοντέλο: TZ-110 Ισχύς: 0.75kw Τάση: 380v/50Hz Βάρος: 280kg Μέγεθος: 3500*800*900mm Ταχύτητα ιμάντα: ρυθμιζόμενη Υλικό: ανοξείδωτο ατσάλι 304 |

| 4. κοπής πατάτας |  | Μοντέλο: TZ-600 Ισχύς: 1.1kw Τάση: 380v/50Hz Βάρος: 120kg Μέγεθος: 950*800*950mm Χωρητικότητα: 600kg/h Υλικό: ανοξείδωτο ατσάλι 304 Σημειώσεις: η τιμή περιλαμβάνει μόνο 1 σετ λεπίδων, αν θέλετε διαφορετικό μέγεθος, αλλάξτε τις λεπίδες. |

| 5. ανυψωτής δοχείου νερού |  | Μοντέλο: TZ-200 Ισχύς: 0.75kw Τάση: 380v/50hz Βάρος: 330kg Μέγεθος: 1500*800*1600mm Πλέγμα: 500mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 6. επιλογή μηχανής |  | Μοντέλο: TZ-1400 Μέγεθος: 2400*1000*1300mm Ισχύς: 1.1kw Τάση: 380v/50hz Υλικό: ανοξείδωτο ατσάλι 304 Λειτουργία: Επιλογή διαφορετικού μεγέθους πατάτας, που θα κάνει το τελικό μέγεθος πατάτας το ίδιο. |

| 7. ανυψωτική μηχανή |  | Μοντέλο: TZ-4000 Ισχύς: 4.1kw Τάση: 380v/50Hz Βάρος: 400kg Χωρητικότητα: 800kg/h Μέγεθος: 4000*1200*1300mm πλάτος ιμάντα: 800mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 8. μηχανή λεύκανσης |  | Μοντέλο: TZ-6000 βάρος: 1200kg μέγεθος: 5000*1200*2400mm Χωρητικότητα: 600kg/h Θερμοκρασία: 95 βαθμοί Πλάτος ιμάντα: 800mm Τύπος θέρμανσης: Ηλεκτρική καύση Ισχύς: 500000kcal Υλικό: ανοξείδωτο ατσάλι 304 |

| 9. δονητής νερού |  | Μοντέλο: TZ-800 Ισχύς: 0.5kw Τάση: 380v/50Hz Μέγεθος: 1800*1000*900mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 10. αερόψυκτρο |  | Μοντέλο: TZ-300 Ισχύς: 6,5kw Τάση: 380v/50Hz Βάρος: 700kg Μέγεθος: 4000*1200*1600mm Ανεμιστήρας: 8 τεμάχια Ισχύς ανεμιστήρα: 0.75kw Πίεση αέρα: 120pa Ταχύτητα: 2800r/min πλάτος ιμάντα: 800mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 11. ανυψωτής |  | Μοντέλο: TZ-120 Ισχύς: 0.75kw Τάση: 380v/50hz Βάρος: 180kg Μέγεθος: 1500*800*1300mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 12. μηχανή τηγανίσματος |  | Μοντέλο: TZ-6000 βάρος: 1200kg μέγεθος: 6000*1200*2400mm Χωρητικότητα: 600kg/h θερμοκρασία: 95 βαθμοί Πλάτος ιμάντα: 800mm Τύπος θέρμανσης: Ηλεκτρική Ισχύς καυστήρα: 500000kcal Μάρκα καυστήρα: Ιταλία liya road Υλικό: ανοξείδωτο ατσάλι 304 |

| 13. δοχείο λαδιού |  | Ισχύς αντλίας λαδιού: 1.5KW/ 380V/50Hz Μέγεθος: 1400*1300*1850mm Υλικό: ανοξείδωτο ατσάλι 304, ο δοχείο αποθήκευσης λαδιού είναι εξοπλισμένος με λειτουργία θέρμανσης, με φίλτρο, και πάχος 3mm, με μονωτική στρώση. |

| 14. φίλτρο λαδιού |  | Διάμετρος ακατέργαστου φίλτρου: 300mm Μέγεθος δοχείου φίλτρου λεπτού: 450mm Αντλία κυκλοφορίας: 1.5kw |

| 15. δεξαμενή καυσίμων |  | 1. Το δοχείο καυσίμου διαθέτει συσκευή θέρμανσης. 2. Το λάδι που χρειάζεται να προστεθεί θερμαίνεται σε ορισμένη θερμοκρασία μέσω θερμαντικού σωλήνα και στη συνέχεια αποστέλλεται στον εσωτερικό χώρο του τηγανιού μέσω κυκλοφορούντος αντλητικού συστήματος για την επίτευξη του σκοπού της προσθήκης λαδιού. |

| 16. μηχανή δόνησης λαδιού |  | Μοντέλο: TZ-800 Ισχύς: 0.5kw Τάση: 380v/50Hz Μέγεθος: 1800*1000*900mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 17. αερόψυκτρο |  | Μοντέλο: TZ-300 Ισχύς: 6,5kw Τάση: 380v/50Hz Βάρος: 700kg Μέγεθος: 4000*1200*1600mm Ανεμιστήρας: 8 τεμάχια Ισχύς ανεμιστήρα: 0.75kw Πίεση αέρα: 120pa Ταχύτητα: 2800r/min πλάτος ιμάντα: 800mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 18. ανυψωτής |  | Μοντέλο: TZ-120 Ισχύς: 0.75kw Τάση: 380v/50hz Βάρος: 180kg Μέγεθος: 1500*800*1300mm Υλικό: ανοξείδωτο ατσάλι 304 |

| 19. ψυγείο |  | Μοντέλο: TZ-10000 Εξωτερικές διαστάσεις: 160000*3300*2600mm Συμπιεστής: 150hp Ισχύς πλέγματος: 2.2kw Ανεμιστήρας: 12 τεμάχια * 1.5kw Μηχανή ιμάντα πλέγματος: Siemens PLC: Siemens SUS 304 Πάχος εσωτερικού κουτιού: 0.8mm Εξωτερικό πάχος: 0.8mm Εσωτερικό Μονωτική βαμβακερή μόνωση: 120mm Συμπιεστής: Γερμανίας Bitzer Ένα τμήμα: 30Τ συνολικά 3 τμήματα σε παράλληλη λειτουργία Σημείωση: Τιμή με τιμή συμπιεστή |

| Μηχανή συσκευασίας 20 |  | Α. Μεταφορικός ιμάντας τροφοδοσίας Αξία παράδοσης: 3-6m³/h Τάση: 380v Βάρος: 500kg B.TZ-720 κάθετη αυτόματη μηχανή συσκευασίας Μήκος σακούλας: 100-400mm (L) Πλάτος σακούλας: 180-350mm (W) Μέγιστο πλάτος ταινίας: 720mm Ταχύτητα συσκευασίας: 5-50 σακούλες/λεπτό Εύρος μέτρησης: 6000ml (Μέγιστο) Κατανάλωση αέρα: 0.65Mpa Κατανάλωση αερίου: 0.4m³/λεπτό Τάση: 220VAC/50HZ Ισχύς: 5kw Διαστάσεις: 1780*1350*1950mm Σημειώσεις: Περιλαμβάνει σακούλα προ-μορφής C.10 κάδοι πολυκεφαλικοί ζυγιστικοί μηχανές Μέγιστο βάρος ζύγισης: 1000g Μονάδα ζύγισης: 10-1000g Ακρίβεια ζύγισης: ±0.3~1.5g Ταχύτητα ζύγισης: Μέγιστο 3000cc Μονάδα ελέγχου: οθόνη 8.4 ιντσών D. Πάγκος αντιολισθητικός, με προστατευτικό κιγκλίδωμα, πρακτικός και ασφαλής. Επίπεδο τελικού προϊόντος μεταφορέας |

| 21. fκατάψυξη και αποθήκευση τηγανητών πατάτας 10 τόννων, -20°C |  | Μέγεθος: 5*5*2.4m Πάχος 100mm από χάλυβα χρωμίου πολυουρεθάνης: 98m² Kumen: 1 Η μονάδα αυξάνει τη διαχείριση θερμότητας 80 ψυγείων 8 άλογα: 1 σετ Ψυκτικό αέρα: 1 Αυτόματο ηλεκτρονικό ντουλάπι ελέγχου απόψυξης: 1 σετ Βαλβίδα ηλεκτρομαγνητικού διακόπτη: 1 Βαλβίδα επέκτασης: 1 Freon: 25kg Κυβώτια σώματος βιβλιοθήκης και υλικά στεγανοποίησης διακόσμησης: 71m² Καλώδιο γραμμής και φωτισμός ανθεκτικός στην υγρασία, κ.λπ.: 1 ομάδα Σύστημα σωληνώσεων και μόνωση: 1 σετ |

Πλήρως αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας βίντεο λειτουργίας

Χαρακτηριστικά της αυτόματης γραμμής παραγωγής πατάτας τηγανητής

- Η αυτόματη γραμμή παραγωγής τηγανητών πατάτας, προσθέτει πολλούς ανυψωτές που συνδέουν δύο αυτόματες μηχανές επεξεργασίας πατάτας. Επομένως, η αυτοματοποιημένη γραμμή παραγωγής τηγανητών πατάτας χρειάζεται μόνο ένα ή δύο άτομα για τον έλεγχο της οθόνης της μηχανής για λειτουργία.

- Για τον πλήρη καθαρισμό των ακαθαρσιών στα πατατάκια, η γραμμή παραγωγής προσθέτει πλυντήριο για επιλογή μεγέθους των δακτυλίων. Ο επιλογέας μπορεί να διαλέξει τα κατάλληλα μεγέθη τηγανητών, και τα μικρότερα θα πέφτουν. Αυτό διασφαλίζει την ποιότητα των τηγανητών. Η μηχανή είναι επίσης το μεγαλύτερο σημάδι που διακρίνει το εργοστάσιο τηγανητών από τη γραμμή πατατάκια.

- Χρησιμοποιεί τη δονητική μηχανή απομάκρυνσης νερού και λαδιού στη μονάδα επεξεργασίας. Σε σύγκριση με τη μικρή γραμμή τηγανητών, μπορεί να μεταφέρει τις πατάτες στο επόμενο μηχάνημα ενώ επιτυγχάνει λειτουργίες απομάκρυνσης νερού και λαδιού. Επιπλέον, μπορεί να πραγματοποιήσει αυτόματη συλλογή νερού ή λαδιού.

- Η πλήρης αυτόματη γραμμή παραγωγής κατεψυγμένων τηγανητών πατάτας χρησιμοποιεί συνεχές μηχάνημα λευκασμού και τηγανίσματος. Το μηχάνημα διαθέτει λειτουργίες αυτόματης μεταφοράς υλικών, ελεγχόμενης θερμοκρασίας και χρόνου τηγανίσματος, αυτόματης καθαριότητας του κάτω μέρους της μηχανής και συλλογής καπνού λαδιού.

- Το μέγεθος του καταψύκτη κατεψυγμένων τηγανητών πρέπει να καθοριστεί σύμφωνα με την παραγωγική απόδοση του πελάτη. Επιπλέον, παρέχουμε διάφορους τύπους μηχανών συσκευασίας, που μπορούν να επιτύχουν μεγάλη χωρητικότητα, πολλαπλές παρτίδες, ποσοτική συσκευασία. Ο πελάτης πρέπει να παρέχει το μέγεθος και το βάρος της συσκευασίας.

Προφυλάξεις για την ανάπτυξη της επιχείρησης κατεψυγμένων τηγανητών

1. Πρώτα απ' όλα, πρέπει να γνωρίζετε σαφώς το τελικό προϊόν που χρειάζεται να παρασκευάσετε και το μέγεθός του. Τα μεγέθη των κατεψυγμένων τηγανητών πατάτας σε διαφορετικές περιοχές δεν είναι ακριβώς τα ίδια. Το πιο δημοφιλές μέγεθος τηγανητών πατάτας είναι 3-7mm, αλλά υπάρχουν ορισμένες διαφορές στο πιο δημοφιλές μέγεθος σε διάφορα μέρη.

2. Πριν ξεκινήσετε την επιχείρηση παραγωγής τηγανητών, πρέπει να πραγματοποιήσετε λεπτομερή έρευνα της τοπικής αγοράς τηγανητών για να κερδίσετε από την παραγωγή. Για παράδειγμα, οι ποικιλίες πατάτας και οι τιμές τους, η διαθεσιμότητα, κ.λπ.

3. Μπορείτε να επιλέξετε τη γραμμή παραγωγής τηγανητών που ταιριάζει στην παραγωγική σας κατάσταση σύμφωνα με την κατάσταση ή τον προϋπολογισμό του εργοστασίου σας. Ανεξάρτητα από τη γραμμή που επιλέγετε, μπορούμε να δημιουργήσουμε ένα μοναδικό σχέδιο παραγωγής για εσάς σύμφωνα με το εργοστάσιό σας.

Πώς να ξεκινήσετε μια επιχείρηση τηγανητών πατάτας κατά τη διάρκεια πανδημίας;

Κατά τη διάρκεια της πανδημίας, η παραγωγή και οι πωλήσεις πολλών εργοστασίων έχουν επηρεαστεί σε κάποιο βαθμό. Ωστόσο, μερικές δημοφιλείς μάρκες κατάφεραν να επεκτείνουν την επιχείρησή τους. Είναι χρήσιμο να γνωρίζετε αποτελεσματικές στρατηγικές για την εκκίνηση της επιχείρησης τηγανητών πατάτας κατά τη διάρκεια της πανδημίας για να αναπτύξετε την επιχείρησή σας.

Συγκεκριμένες περιπτώσεις πωλήσεων γραμμών παραγωγής κατεψυγμένων τηγανητών πατάτας

Πλήρως αυτόματη γραμμή παραγωγής τηγανητών πατάτας που λειτουργεί στην Τουρκία

Μηχανή τηγανητών πατάτας στην Αυστραλία

Αιγύπτιοι πελάτες επισκέφθηκαν το εργοστάσιο μηχανημάτων τηγανητών μας

Ο πελάτης από το Ιράκ αγόρασε πλήρη αυτόματη γραμμή παραγωγής τηγανητών πατάτας 200kg/h

Καλώς ήρθατε στην επίσκεψη στο εργοστάσιο μηχανημάτων τηγανητών πατάτας Taizy