Les frites ont toujours été les produits phares de McDonald's, et presque tous les clients commanderont des frites McDonald's. Pourquoi les frites McDonald's sont-elles populaires ? Quels sont les points particuliers concernant les pommes de terre qu'ils choisissent comme matériau de ligne de production de frites?

Utilisez uniquement des variétés de pommes de terre de la plus haute qualité

Dans le manuel qualité de McDonald's, seules trois sortes de pommes de terre peuvent être incluses dans la liste des ingrédients pour Ligne de transformation de frites, c'est-à-dire Shapotti, Polbank et Innovator. Après tests, la teneur en amidon de ces trois types de pommes de terre est la plus modérée, qui peut être utilisée comme matière première pour la chaîne de production de frites. Le goût est plein après avoir fait des chips. De plus, avec une forme ellipse et une taille modérée, l'œil du bourgeon à la surface est légèrement moins profond que celui des pommes de terre ordinaires. Ainsi, la longueur des frites après découpe est plus nette, sans taches.

Il faut quatre générations à partir de plants de pommes de terre pour entrer dans le Usine de transformation de frites. Par conséquent, les frites que vous avez dégustées au restaurant McDonald’s ont commencé à se développer il y a trois ans déjà. Ce n'est qu'après un contrôle strict de la sélection des plants et du processus de sélection que la pomme de terre peut conserver ses excellents gènes, réduisant ainsi considérablement le risque de ravageurs et de maladies.

L'environnement de culture approprié

La croissance des pommes de terre impose des exigences strictes en matière de pH du sol et de qualité du sable. La base de plantation de pommes de terre de McDonald's dispose d'air frais, d'eau d'irrigation de haute qualité et loin des sols contaminés.

McDonald's surveille strictement la teneur en métaux lourds du sol pour garantir la croissance sûre des pommes de terre. Grâce au système d’irrigation avancé au monde, il peut répondre pleinement aux besoins nutritionnels de chaque plante. Afin d'assurer une croissance saine des pommes de terre, celles-ci sont également soumises à une rotation. Les pommes de terre sont cultivées sur la même terre tous les un à deux ans, ce qui leur offre un environnement pédologique de haute qualité.

Traitement précis des pommes de terre

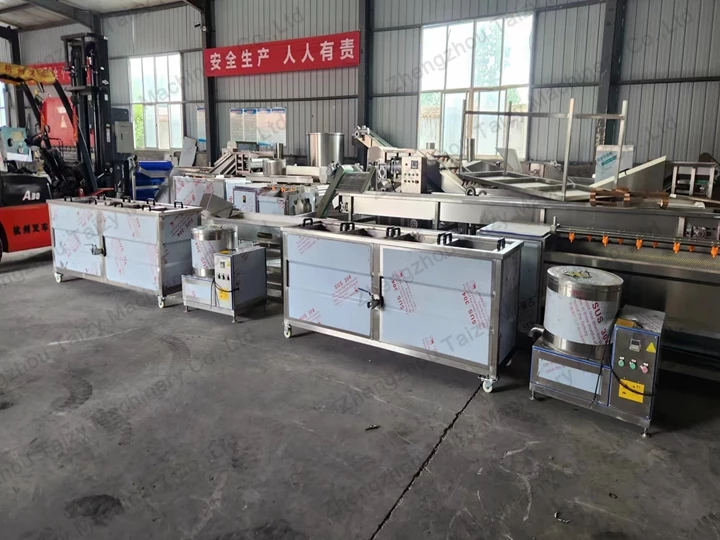

Dans le ligne de production de frites, la transformation des pommes de terre en frites passe par de nombreuses étapes telles que l'épluchage, la découpe, le blanchiment, le séchage, la friture, la surgélation, l'emballage, etc. Conformément aux normes de qualité uniformes mondiales de McDonald's, un système de gestion de la qualité strict joue un rôle essentiel. McDonald's procède régulièrement à des échantillonnages et à une certification tierce des frites. Les frites ont des normes de comparaison fines en termes de texture, de couleur, de forme et de défauts. Les frites qui dépassent la gamme approuvée ne finiront pas par entrer dans les McDonald's.

Basé sur la fourniture du meilleur service aux consommateurs, McDonald's dispose également d'un système d'évaluation sensorielle unifié à l'échelle mondiale. C'est-à-dire que grâce à l'évaluation sensorielle de la couleur, de l'arôme et du goût, la qualité des frites est enfin vérifiée. Ce concept garantit que les consommateurs peuvent déguster des frites vraiment délicieuses chez McDonald's, et pas seulement celles qui répondent aux normes.