The potato chip seasoning machine is used for seasoning potato chips. Seasoning is the most important step in the potato chip production line, which directly affects the final taste of potato chips. Therefore, the choice of seasoning machine is also very important. According to the shape of the seasoning machine, it can be divided into two types, one is the octangle seasoning machine, and another is the drum seasoning machine.

Type one: octagonal chips seasoning machine

The octagonal seasoning machine is named after its appearance. According to the different discharging methods, it divides into manual discharging and automatic discharging machines. And according to the different output of customers, the machine has single-head, double-head, three-head, and four-head machines.

Video of potato chips seasoning machine

Technical parameter

| Model | Size | Weight | Power | Capacity |

| CY800 | 1000*800*1300mm | 130kg | 1.1kw | 300kg/h |

| CY1000 | 1100*1000*1300mm | 150kg | 1.5kw | 500kg/h |

| CY2400 | 2400*1000*1500mm | 300kg | 0.75kw | 1000kg/h |

| CY3000 | 3000*1000*1600mm | 380kg | 1.1kw | 1500kg/h |

Advantage of octangle potato chip seasoning machine

- The octagonal design can fully turn the raw materials.

- The potato chips can be mixed evenly, and discharged automatically by tilting, saving time and energy.

- This seasoning machine integrates electromagnetic, light control, electrical control, and digital delay into one, with a high degree of automation.

- Smooth rotation, low noise, and equipped with an automatic discharge handle.

- Wide application. It widely applies to quick-frozen fries, fried potato chips, banana chips, pineapple chips, fried peanuts, fried broad beans, green beans, soybeans, beef grains, shrimp sticks, rice crackers, onion rings, cashew nuts, pistachios, sunflower seeds, puffed foods, snack foods, etc.

- It uses export-grade with copper core and gear driving, and the fried food will not break.

- The seasoning machine equips with a mixing device with convenient operation and high output. It can automatically stir while spreading the seasoning so that the seasoning will not deposit and bond due to different specific gravity.

- Both the rotation speed and tilt angle of the drum can be adjusted, and the amount of seasoning can be controlled.

- The high degree of automation. Our potato chips seasoning machine fully automatic control speed and material capacity, which is suitable for continuous seasoning operation in the assembly line.

Octagonal flavoring machine structure

It consists of the main parts such as the frame, the drum, the drum transmission system, the seasoning system, the seasoning transmission system, and the switchboard.

How to use the chips seasoning machine?

- Slowly start the drum motor to normal speed, and then start the seasoning motor.

- Slowly and continuously feed the potato chips that need to be seasoned from the inlet to the seasoning part manually or by a conveyor.

- Turn on the seasoning motor to spray the seasoning evenly in the drum.

- Check each running part, and confirm whether it can work normally.

- If the speed is too high, you can turn the knob of the inverter to the left to slow the speed.

- If the potato chips move forward too fast in the drum, you can reduce the drum inclination.

- Finally, the machine can automatically pour out the evenly mixed potato chips.

What should you note?

1.When the machine is running slowly or, please check the tightness of the V-belt.

2.After using the machine for a period of time, check the bolts of each fastener. If it is loose, tighten it.

3.The bearing of the octagonal seasoning machine is used for 6 months, please fill in new lubricating oil in time.

Type two: Rotary roller potato chips seasoning machine

The continuous rotary seasoning machine is to season potato chips or french fries in the potato chips (French fries)production line. The chips flavoring machine can apply after the potato chips frying machine. It also applies to seasoning other food. It equips with a tilting seasoning roller, and you can control the rotary speed. Thus, it widely applies to continuous line seasoning. The spiral powder feeding device can be stir autonomously while mixing. This seasoning machine has integrated electromagnetic, electronic control and digital delay, and high automation as a whole.

Technical parameter

| Model | Size(mm) | Weight(kg) | Power | Capacity |

| CY2400 | 2400*1000*1500 | 300 | 0.75 | 1000kg/h |

| CY3000 | 3000*1000*1600 | 380 | 1.1 | 1500kg/h |

The structure of rotary potato chips flavoring machine

The rotary seasoning machine mainly consists of a bracket, roller, drum drive system, dusting system, dusting drive system, and switchboard.

Advantage of rotary chips seasoning machine

- All parts of the potato chips flavoring machine adopt stainless steel.

- When the double-drum flavoring machine is in operation, the raw materials can run separately on the respective drums. The spices are evenly distributed on the product surface, which can be used for products with different shapes.

- The double-drum seasoning line can spray liquid and powdery seasoning at the same time, and the seasoning effect is good.

- Wide application. This equipment is suitable for seasoning various puffed foods, such as fries and potato chips.

- It is suitable for continuous production lines such as potato chips production line and French fries production line

- Our seasoning machine bears automatic mixing when feeding the seasoning powder, saving time and energy.

- It adopts imported stainless steel bearing, chain rotation, variable frequency speed regulation, adjustable drum speed,

- On the top of the machine, it equips with a seasoning box, which can freely adjust the amount of seasoning according to the actual situation and the required taste of food.

- It matches with the spray pump and heat pump, and it can also be used to spray syrup, soup seasoning, and oil, etc.

What should you need to know before using rotary seasoning machine?

- When the machine is powered on, please check the integrity of the power cord and switch.

- Check the power supply voltage matches.

- You need to place the seasoning machine on dry, level ground to ensure that it works smoothly and reliably.

- Carefully check whether the fasteners on the machine are loose and whether there is any abnormality in each transmission part.

The working steps of potato chips flavoring machine

When the starting rotary seasoning machine starts, the raw material falls into the drum and is moved upward by the stirring blades. Then they drop from above and mix with the seasoning powder. During the working process, the seasoning powder is always kept in the seasoning box. You need to add enough seasoning in the box if it is insufficient.

Working video of chips seasoning machine

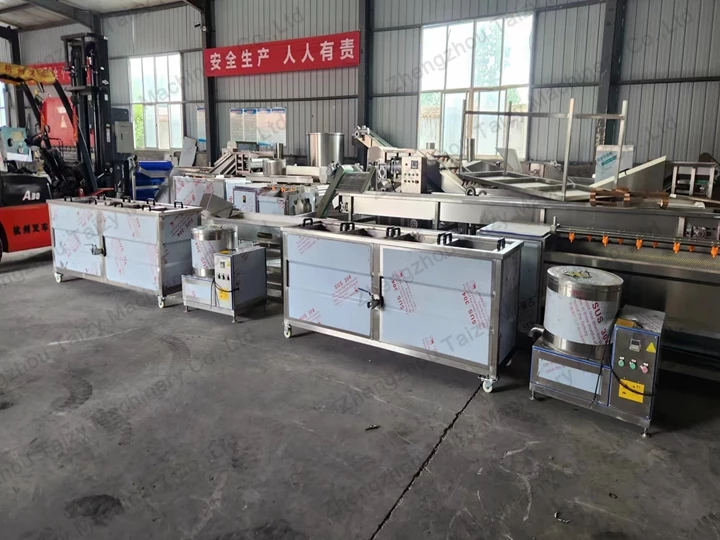

Why choose the Taizy potato chip seasoning machine?

Both potato chip seasoning machines adopt food-grade stainless steel. They can be applied to small potato chip production lines and large processing plant. The most important thing is that these two potato chip seasoning machines can mix the ingredients evenly and will not damage the potato chips.