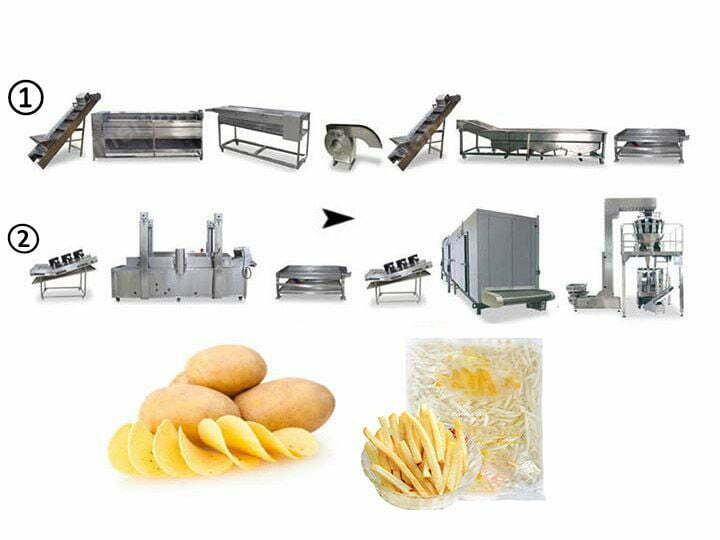

Οι τηγανητές πατάτες είναι ένα πολύ δημοφιλές γρήγορο φαγητό και αναψυκτικό σε μεγάλο αριθμό χωρών. Οι κατεψυγμένες τηγανητές πατάτες είναι κοινά προϊόντα πατάτας που επεξεργάζονται με αποφλοίωση, κοπή, λευκάσμα, ξήρανση, γρήγορο τηγάνισμα, αφαίρεση λαδιού και γρήγορη κατάψυξη. Οι ημι-τηγανισμένες κατεψυγμένες πατάτες συχνά παραδίδονται σε εστιατόρια ταχυφαγίας για να τηγανιστούν και να είναι έτοιμες για κατανάλωση. Η πλήρως αυτόματη μηχανή για τηγανητές πατάτες διαθέτει πλεονεκτήματα αυτόματης, εξειδικευμένης και μεγάλης παραγωγής, λογικής επένδυσης, χαμηλής κατανάλωσης ενέργειας, πολλαπλών λειτουργιών, απλής λειτουργίας, εύκολης χρήσης, συντήρησης κ.λπ. Η ολοκληρωμένη γραμμή παραγωγής κατεψυγμένων τηγανητών πατατών περιλαμβάνει καθαρισμό και αποφλοίωση, κοπή, λευκάσμα, αποξήρανση, τηγάνισμα, απομάκρυνση λαδιού, κατάψυξη, συσκευασία και βοηθητικό εξοπλισμό. Η αυτόματη μηχανή παραγωγής τηγανητών πατατών είναι κατάλληλη για τη παραγωγή μεσαίου και μεγάλου μεγέθους επιχειρήσεων επεξεργασίας πατατών.

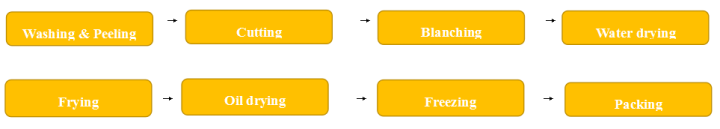

Διαδικασία παραγωγής κατεψυγμένων τηγανητών πατατών

1. Πλύσιμο και αποφλοίωση: Καθαρίστε τη λάσπη στην επιφάνεια των πατατών και αφαιρέστε το δέρμα των πατατών.

2. Κοπή σε λωρίδες: Κόψτε τις πατάτες σε λωρίδες με μήκος περίπου 3mm-12mm.

3. Λευκάσμα: Λευκάστε τις κομμένες πατάτες για να προστατεύσετε το χρώμα, διαφορετικά οι πατάτες θα οξειδωθούν και θα γίνουν καφέ.

4. Αποξήρανση: Αφαιρέστε την περίσσεια νερού πριν το τηγάνισμα για διευκόλυνση και βελτίωση της γεύσης.

5. Τηγάνισμα: Η συνεχής μηχανή τηγανίσματος στην πλήρως αυτόματη μηχανή τηγανητών πατατών ελέγχει αυτόματα τη θερμοκρασία για το τηγάνισμα, και η θερμοκρασία είναι 160-180 βαθμοί Κελσίου. Συνήθως διαρκεί 40-60 δευτερόλεπτα για το τηγάνισμα.

6. Απομάκρυνση λαδιού: Η μηχανή απομάκρυνσης λαδιού με φυγόκεντρο απομακρύνει το φρεσκοτηγανισμένο French fries, ξεπερνώντας τα ελαττώματα υψηλού περιεχομένου λαδιού και λιπαρής γεύσης των τηγανητών πατατών.

7. Γρήγορη κατάψυξη: Οι πατάτες πρέπει να καταψύχονται σε καταψύκτη στους -40 βαθμούς Κελσίου για 15-45 λεπτά. Οι πατάτες καταψύχονται και διαμορφώνονται για εύκολη αποθήκευση και μετέπειτα πώληση και επεξεργασία.

8. Αυτόματη συσκευασία: Η αυτόματη μηχανή συσκευασίας μπορεί γρήγορα να συσκευάσει τις πατάτες σύμφωνα με το καθορισμένο βάρος.

Βίντεο της πλήρως αυτοματοποιημένης γραμμής παραγωγής τηγανητών πατατών

Πλεονεκτήματα αγοράς της πλήρως αυτόματης μηχανής τηγανητών πατατών.

- Υλικό μηχανής: Οι μηχανές στη γραμμή επεξεργασίας κατεψυγμένων τηγανητών πατατών είναι κατασκευασμένες από ανοξείδωτο ατσάλι 304. Συμμορφώνονται με τα πρότυπα ασφάλειας τροφίμων.

- Υψηλή απόδοση: η αυτόματη μηχανή παραγωγής τηγανητών πατατών είναι εύκολη στη λειτουργία, πραγματικά επιτυγχάνει αυτόματη και σταθερή λειτουργία, και υψηλή αποδοτικότητα.

- Εύκολη στη λειτουργία και συντήρηση, και εξοικονόμηση εργασίας. Η λειτουργία και η συντήρηση είναι βολική. Προσφέρουμε ολοκληρωτική after-sales υπηρεσία.

- Τεχνική υποστήριξη. Για επιχειρηματίες αρχάριους, μπορούμε να παρέχουμε δωρεάν φόρμουλα παραγωγής και ολοκληρωμένη τεχνική υποστήριξη στους πελάτες μας.

Προδιαγραφές της αυτόματης γραμμής παραγωγής τηγανητών πατατών 500kg/h

| Όνομα μηχανής | Μοντέλο: 500kg/h | Ανελκυστήρας |

| Αυτόματη ανύψωση και τροφοδοσία, βολική, αποδοτική και γρήγορη, εξοικονομώντας εργατικό δυναμικό. | μέγεθος: 2500*1050*1400mm | Μήκος κυλίνδρου: 800mm Πλήρης αυτόματη μηχανή καθαρισμού και αποφλοίωσης πατάτας, υψηλή αποδοτικότητα και εξοικονόμηση ενέργειας, εξοικονόμηση χρόνου και κόπου. Power: 0.75kW Υλικό: 304SS |

| Μηχανή Πλύσης και peeling Πατάτας | Χειροκίνητη ζώνη επιλογής | Μέγεθος: 3600*850*900 mm Μήκος κυλίνδρου: 2600mm Ισχύς: 5.5kw Υλικό: 304SS |

| Αφαιρέστε τις κακές τρύπες και ουλές των πατατών για βελτίωση της ποιότητας. | μέγεθος: 4000*1050*800mm | Αποτελεσματική κοπή λωρίδων με ρυθμιζόμενο μέγεθος Πλήρης αυτόματη μηχανή καθαρισμού και αποφλοίωσης πατάτας, υψηλή αποδοτικότητα και εξοικονόμηση ενέργειας, εξοικονόμηση χρόνου και κόπου. Ισχύς: 1,1kw Υλικό: 304SS |

| Μηχανή Κοπής Τηγανητών Πατάτας | Ανεβάστε τις λωρίδες πατάτας στο μηχάνημα λευκάσματος πατάτας. | Μέγεθος: 850 * 850 * 1000 mm Power: 0.75kW Μέγεθος κοπής: 3-8mm Υλικό: 304SS |

| Αυτόματη ανύψωση και τροφοδοσία, βολική, αποδοτική και γρήγορη, εξοικονομώντας εργατικό δυναμικό. | Αφαιρέστε το άμυλο στην επιφάνεια των λωρίδων πατάτας και αναστείλετε τη δραστηριότητα των ενεργών ενζύμων. | Μήκος κυλίνδρου: 800mm Πλήρης αυτόματη μηχανή καθαρισμού και αποφλοίωσης πατάτας, υψηλή αποδοτικότητα και εξοικονόμηση ενέργειας, εξοικονόμηση χρόνου και κόπου. Power: 0.75kW Υλικό: 304SS |

| Μηχανή λεύκανσης πατάτας | Ηλεκτρική ισχύς θέρμανσης: 240 kw | Μέγεθος: 8000*1350*1250mm Πλάτος ιμάντα πλέγματος: 1000mm Μηχανή ξήρανσης νερού Υλικό: 304SS |

| Αφαιρέστε τα κομμάτια που είναι πολύ μικρά και δονήστε για να αφαιρέσετε την υπερβολική ποσότητα νερού. | μέγεθος: 1000*1200*1100mm | Πλάτος πλέγματος: 1000mm ισχύς: 21kw βάρος: 420kg Μηχανή τηγανίσματος πατάτας |

| Συνεχίστε το τηγάνισμα των πατατών υπό ακριβή έλεγχο θερμοκρασίας και χρόνου. | Ηλεκτρική ισχύς θέρμανσης: 320 kw | Μέγεθος: 10000*1450*1550mm Πλάτος ιμάντα πλέγματος: 1000mm Δονήστε για να αφαιρέσετε την υπερβολική ποσότητα λαδιού και να βελτιώσετε τη γεύση. Υλικό: 304SS |

| Μηχανή Ξήρανσης Λαδιού | και μεταφέρει το υλικό στο επόμενο μηχάνημα Μηχανή ξήρανσης αέρα | μέγεθος: 1200*700*750mm βάρος: 420kg Ισχύς: 2.2kw |

| Ξεβγάλτε το επιπλέον λάδι από την επιφάνεια και κρυώστε καλά τις πατάτες για να μπουν στον γρήγορο καταψύκτη. | Ισχύς: 7.5KW, 380V/50Hz | Αριθμός ανεμιστήρων: 10 Μέγεθος: 3500x1200x1400mm Οι πατάτες καταψύχονται για περίπου 15-45 λεπτά για εύκολη αποθήκευση και μεταφορά. |

| Γρήγορος Καταψύκτης | Αυτόματη μηχανή συσκευασίας | Μήκος: 15000mm Θερμοκρασία κέντρου κατάψυξης: – 18 ° Υλικό: 304SS |

| Πλήρης αυτόματη συσκευασία κατεψυγμένων πατατών σύμφωνα με τις απαιτήσεις του πελάτη | Ταχύτητα ζύγισης: 60 φορές/λεπτό | Μέγιστο βάρος: 1000g Μοναδιαία ζύγιση: 10-1000g Τα παραπάνω είναι τα γενικά τεχνικά δεδομένα της αυτόματης μηχανής τηγανητών πατατών 500kg/h. Προσφέρουμε επίσης μηχανές τηγανητών πατατών με άλλες χωρητικότητες από 50-2000kg/h. Εάν απαιτούνται ειδικές ανάγκες, μπορούν να παρέχονται προσαρμοσμένες υπηρεσίες. |

Ολοκληρωμένη κατασκευή γραμμής επεξεργασίας κατεψυγμένων τηγανητών πατατών.