Industrial potato fryer machine is widely applied in the food processing industries, so there are many types of food frying technology. According to the air pressure, it can be divided into normal pressure frying and vacuum frying. According to the frying method, it can be divided into continuous frying and intermittent frying.

Normal pressure frying technology

Atmospheric pressure frying refers to the standard atmospheric pressure when the fryer machine is in operation. It is the most commonly used frying technique. Its advantages are easy processing. The final products are crisp with good flavor. The disadvantage is that nutrition and color loss is great. Room temperature frying is more suitable for frying foods such as fried cakes and bread.

Vacuum frying technology

The absolute pressure of vacuum frying is lower than atmospheric pressure, and the frying process is carried out under relative hypoxia. The food processed by this technology can retain the flavor and nutritional components to the maximum extent. It can effectively prevent the oxidative deterioration of edible oils and fats. The features of it are as follows:

1. It can reduce the evaporation temperature of moisture in the material. Compared with normal pressure frying, it bears lower heat energy consumption, greatly reducing the frying temperature. Besides, it can decrease the loss of vitamins, etc. in the food. It is also beneficial to maintaining the nutritional content of the food and avoiding food coking.

2. It can cause an anoxic environment, which can effectively kill bacteria and some harmful microorganisms. In addition, such frying technology is able to reduce the oxidation speed of materials and oil, reducing the mildew and bacterial infection. Thus, it helps prolong the storage period of products

3. The vacuum condition also shortens the time for impregnation, degassing and dehydration.

4. With the help of the pressure difference, it can improve the frying speed.

Intermittent frying technology

When using this technology to fry food, the oil is first heated to the specified temperature, and then you can put the potato into industrial potato fryer machine. After processing, you can add new potatoes. Because the input of potatoes is intermittent, it is called intermittent frying technology.

Its advantages are relatively low technology content, which is suitable for small-scale production. The disadvantage is that the product will cause heat loss during the process, and it takes a long time.

Continuous frying technology

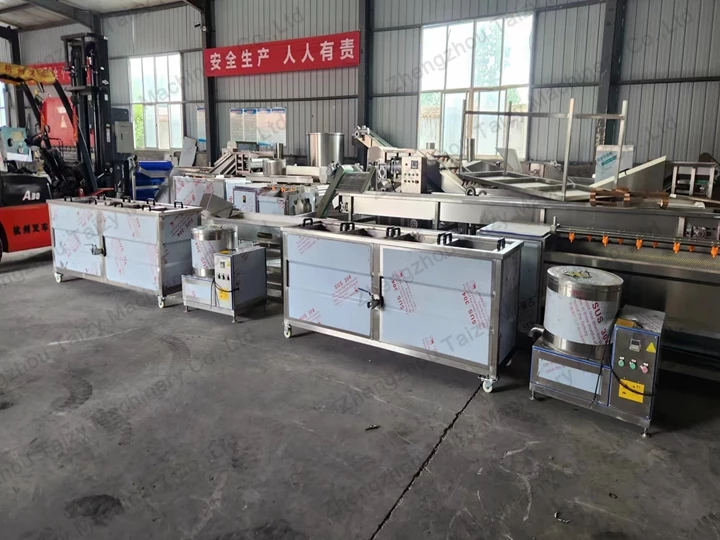

The feeding of the potatoes is continuous. After the material is fed into the industrial potato fryer machine, it moves with the mesh belt in the frying oil. The products processed by this technology have consistent frying temperature and time, so they boast constant appearance, flavor and warranty time. At the same time, this frying method has a good oil filter effect, which can reduce the odor generated by frying.