The potato chips production line contains a series of potato chips machines to make crispy potato chips from raw potatoes. The potato chips manufacturing process mainly includes washing, peeling, slicing, blanching, dewatering, frying, deoiling, flavoring, and packaging.

According to the capacity difference, the fried potato chips production line includes a small chips production line and a fully automatic potato chips processing plant. The small chips line’s capacity ranges from 50kg/h to 300kg/h, while the automatic chips processing plant’s capacity range from 300kg/h to 2t/h.

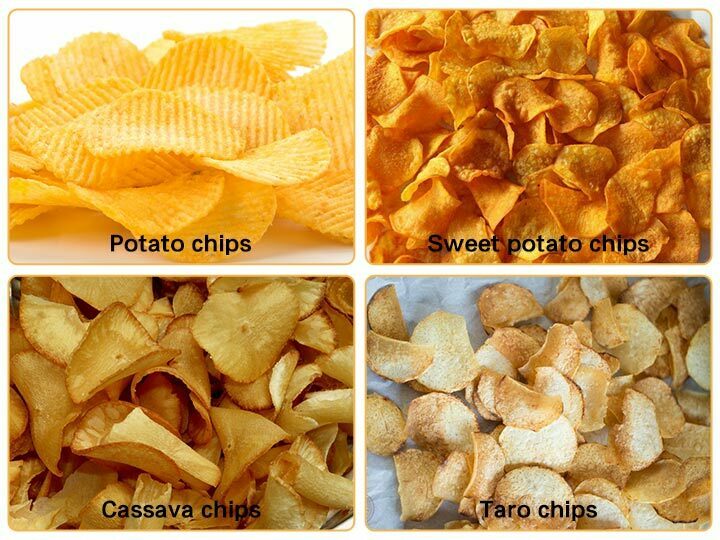

The potato chip processing machine provided by chips machine manufacturers not only can make potato chips, but also sweet potato chips, cassava chips, taro potato chips, etc. The potato chips making machine is popularly applied in restaurants, fast food stores, hotels, canteens, snack food processing factories, etc.

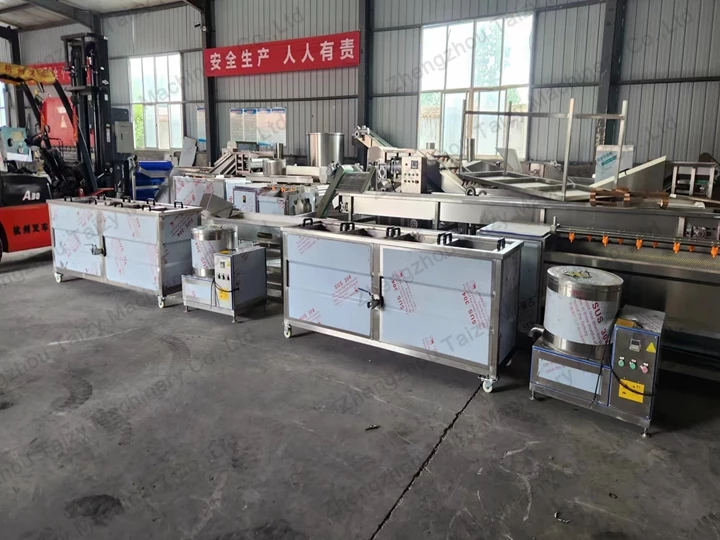

Potato chips production line

The small potato chips production line is mainly composed of semi-automatic potato chips making machines, they need people to manually operate the feeding and discharging. The chips manufacturing process contains washing potatoes, potato slicing/cutting, blanching potato chips, chips dewatering, potato chips frying, chips deoiling, seasoning chips, and packaging.

Semi-automatic potato chips processing plant flow chart

Potato cleaning machine

The main functions of the potato cleaning machine are cleaning and peeling. It can peel off the potatoes while cleaning and has a high cleaning efficiency. The machine consists of 9 hair rollers evenly distributed inside the machine. So it can fully contact the potatoes and thoroughly clean up the impurities on the surface of the potatoes.

potato chips cutting machine

The potato chip slicer machine has the functions of slicing and cutting. The potato chips produced by this machine have the same thickness and complete dicing. You can also meet the production requirements of various potato chip sizes by changing to other sizes and shapes. It is worth mentioning that the potato chip slicer can also be used to make wave potato chips.

chips blanching machine

The main function of potato blanching machine is to remove the starch in the potato to maintain the bright color and taste of the potato chips. This potato chips making machine is made of all 304 stainless steel, and the blanching temperature range is 80-100℃ and can be adjusted.

chips dewatering machine

The dehydrator uses the principle of centrifugation for dehydration. The machine control panel makes the dehydration time adjustable. The dehydration time is 1 to 2 minutes.

potato chips frying machine

The potato chip frying machine is made of all 304 stainless steel, so it can ensure a safe and hygienic environment for frying. The frying temperature of potato chips is generally maintained at 160~180℃, and the frying time is 1-5 minutes. The semi automatic potato chips production line uses a frame fryer. The more frames the machine has, the higher its production efficiency. In order to improve production efficiency, most small potato chip manufacturers often purchase multiple frying boxes.

chips de-oiling machine

The chip deoiling machine has the same working principle as the dehydrator. Its purpose is to remove excess oil on the surface of potato chips to ensure a better taste.

seasoning machine

The octagonal seasoning machine evenly mixes the flavoring and potato chips by rotating continuously. Although the machine is constantly rotating, it will not damage the potato chips. The flavoring machine also has multiple seasoning head models. If you need to spray liquid seasoning, the machine can also add an automatic seasoning spraying device to achieve high automation.

potato chips packing machine

This potato chips packaging machine can be set with all the data before packing, such as the packing size, packing weight, packing speed, etc. This potato chip packing machine can pack 25-35 bags of potato chips per minute. Due to different packaging specifications, the packaging speed is different. Customers can set their own required packaging weight.

Parameters of semi-automatic potato chips production line

| Machine list | Item name | Main parameter |

| 1 | Potato washing & peeling machine | Length of roller: 600-2000mm Power: 1.1-4kw Capacity: 500-2000kg/h |

| 2 | Potato Chips Slicing Machine | Dimension:600*500*900mm Size:2-9mm Power: 1.5kw |

| 3 | Potato blanching machine | Dimension:3000*1150*1250mm Belt width: 800mm Power:60kw |

| 4 | Water drying machine | size:1000*500*700mm weight:200kg power:1.5kw |

| 5 | Potato Chips Frying machine | Dimension: 3000*1150*1550mm Belt width: 800mm Power: 60kw |

| 6 | Oil drying machine | size: 1000*500*700mm weight: 200kg power: 1.5kw |

| 7 | Potato chips Seasoning machine | Dimension: 2400*1000*1500 Power: 0.75kw |

| 8 | Potato chips packaging machine | Maximum weight: 1000g Single weighing range: 10-1000g Weighing speed:60 times/min |

Small potato chips processing line video

Fully automatic crispy potato chips production line

Compared with small potato processing machines, the large chips plant replaced a large-capacity potato chips machine. And in this line, many hoists are added to replace manual feeding and discharging. This automatic potato chip processing line can realize the fully automatic process from raw material feeding to frying and packaging. It has a high degree of automation and covers a wide area. Therefore, this fully automatic potato chips production line is suitable for large potato chip processing plants.

Fully automatic potato chips production line video

Large potato chips processing line process

You can see from the video that the machine in the large potato chips production line has been replaced with an automatic high-volume machine.

- The blanching machine and frying machine have been replaced with mesh belt continuous machines. The mesh belt fryer can control the frying time by controlling the speed of potato chip transportation. The machine controls the frying time and temperature by the PLC display screen. And the machine also has the features of an automatic lifting mesh belt and automatic cleaning.

- The octagonal flavoring machine is replaced with a rotarty drum seasoning machine in the large line. It can realize the continuity of seasoning while realizing automatic feeding.

- For packaging, a four-head or ten-head scale is usually used to achieve large-volume automatic packaging instead of the potato chips packaging machine above.

Semi-automatic potato chips plants VS Full-automatic potato chips production lines

Similarities

- All potato chip processing machines in the line adopt all 304 stainless steel, which is safe, hygienic, and corrosion-resistant.

- All potato chip machines have many different models, so they adapt to the needs of different customers.

- The fryer and blanching machine in the large and small potato chip lines have electric heating, air heating, and other heating methods.

- Both potato chip production lines can produce potato chips of different shapes and sizes by changing the blade of the slicing machine.

Differences

- Small-scale and large-scale production lines have different outputs. The output of the small-scale production line is between 50-300kg/h, and the output of a large-scale is between 300kg/h-2t/h.

- All machines of the large potato chips production line can be customized according to customer requirements.

- It has various differences between the two lines for labor, site area, budget, and energy consumption.

- The semi-automatic potato chip production line has a high degree of flexibility, and it can be replaced by the same function machine. Therefore, small potato chips manufacturers may purchase different chips machines. The large potato chip plant does not have so much flexibility.

- It is recommended that the workshop area required by the semi-automatic potato chip line should be less than 200 square meters. (about 50 square meters for 50kg/h, about 100 square meters for 100kg/h, and about 200 square meters for 200kg/h). The fully automatic potato chip production line generally requires a plant area of more than 500 square meters.

Advantages of the potato chips processing line

- The potato chips production line has different output, which meets the requirements of large, medium, and small potato chip manufacturers

- All chips machines are made of all 304 food-grade stainless steel, which has the characteristics of high efficiency, energy-saving, safety, and health.

- The potato chips production line has the characteristics of continuous work, which can realize the entire process from raw materials to final products.

- It is not only suitable for the production of potato chips but also can meet the production of sweet potato chips, cassava chips, and other production chips. It can realize the needs of one machine for multiple products.

- This production line has high production efficiency and low input cost. It is the best choice for potato chip manufacturers to invest in manufacturing potato chips.

What is the potato chips production line price?

For most people, it is a concern for the potato chips processing line price. Because the potato chip production line has a variety of different outputs. Different capacity production lines with different costs. Moreover, customers may also have other requirements or purchase other accessories. Therefore, the price factors influencing the potato chip production line are diverse.

Parameters of automatic potato chips production line

| Item | Parameter |

| Hoist conveyor | Model: TZ-11 Power:0.55kw Voltage:380v/50Hz Size:1500*800*1600mm Weight:160kg Material: All SUS 304 This machine can adjust the speed manually, which can save time and energy. |

| Screw brush washing machine | Model: TZ-2000 Power:3.37kw Voltage:380v/50Hz Size:2800*1000*1400mm Weight:450kg Material: All SUS 304 There is a hair roller inside the machine, which can quickly rub the skin of the potato. There is a spiral to polish the potatoes. |

| Picking conveyor | Model: TZ-2500 Voltage:380v/50hz, 3 phrase Power:0.75kw Weight:300kg Size:4000*700*900mm |

| Water bucket hoist | Model: TZ-1500 Power:0.75kw Voltage:380v/50hz Weight:330kg Size:2000*950*1600mm Material: 304 stainless steel |

| Chips cutting machine | Model: TZ-1000-1 Size:1000*600*1500mm Chip thickness:2mm Material: The blade is made of high-speed stainless tool steel, the turntable is made of high-quality aluminum-magnesium alloy, and the rest is made of 304 stainless steel |

| Bubble washing machine | Model: TZ-3000 Length:3m Belt width:800mm Size:3000*1200*1300mm Weight:300kg Material:304 stainless steel |

| Blanching machine | Model: TZ-3500 Size: 3000*1100*1300mm Belt width:800mm Heating method: electric Weight:300kg The blanching machine with 2 lifting devices |

| De-water machine | Model: TZ-800 Power:0.5kw Voltage: 380v/50Hz Size:1800*1000*900mm Material: 304 stainless steel |

| Air cooling machine | Model: TZ-3000-1 Size: 3000*1200*1600mm Weight: 400kg Power: 7.5kw Fans: 6 Belt width: 800mm |

| Hoist conveyor | Model: TZ-120 Power: 0.75kw Voltage:380v/50hz Weight:180kg Size:1500*800*1300mm Material: 304 stainless steel |

| Frying machine | Model: TZ-3500 Size:3500*1200*2400mm Belt width:800mm Weight:1200kg Heating method: electric The frying machine with 2 lifting devices |

| Oil tank | Oil pump motor power: 1.5KW/ 380V/50Hz Size: 1400*1300*1850mm Material:304 stainless steel. The oil storage tank is equipped with a heating function, with a filter, and the thickness is 3mm, with an insulation layer. |

| Oil filter | Coarse filter tank diameter: 300mm Fine filter tank size: 450mm Circulating pump:1.5kw |

| De-oil machine | Model: TZ-800 Power:0.5kw Voltage:380v/50Hz Size:1800*1000*900mm Material: 304 stainless steel |

| Air cooling machine | Model: TZ-3000-1 Size:3000*1200*1600mm Weight:400kg Power:7.5kw Fans:6 Belt width:800mm |

| Hoist conveyor | Model: TZ-120 Power:0.75kw Voltage:380v/50hz Weight:180kg Size:1500*800*1300mm Material: 304 stainless steel |

| Seasoning machine | Model: TZ-2400 Size: 2400*1000*1600mm Power:1.5kw Voltage:380v,50hz,3 phases |

| 10-head fully automatic packing machine | A. Feed conveyor Delivery Volume:3-6m³/h Voltage:380v Weight:500kg B.TZ-720 Vertical Automatic Packaging Machine Bag length:100-400mm(L) Bag width:180-350mm(W) Max width of roll film:720mm Packing speed:5-50bags/min Measuring range:6000ml(Max) Air consumption:0.65Mpa Gas consumption:0.4m³/min Voltage:220VAC/50HZ Power:5kw Dimension:1780*1350*1950mm C.10 Buckets Multi Head Weigher Machine Maximum weighing:1000g Single weighing range:10-1000g Weighing accuracy:±0.3~1.5g Weighing speed: Max 3000cc Control unit:8.4 inch key screen D.Platform Non-slip countertop, guardrail around, practical and safe. E.Finished product conveyor Packing weight: less than 2.5kg |

The above shows the general technical data of our potato chip processing lines. As a potato chip machine manufacturer, we provide automatic and semi-automatic machines of different capacities to meet customers’ demands.

Supporting equipment is also available. Generally, the larger the size of the machine, the higher the output. For instance, the potato washing and peeling machine vary with its roller length. For special needs, we can customize the machine accordingly.

The following are the potato chip processing plants with different outputs.

200kg/HIndustrial Potato Chips Making Machine

100kg Semi-Automatic Potato Chips Manufacturing Line

50kg/H Small-Scale Automatic Potato Chips Making Line

FAQ about potato chips production solutions

How many potato chips can be made from 1kg of potatoes?

0.3kg potato chips.

How long should I wash potatoes when using a washing machine?

This is based on the freshness of the potatoes you use. If you use fresh potatoes, they generally need 1-2 minutes; for comparison potatoes, they need 5-6 minutes.

Do I need to add anything when blanching? How long is the blanching time?

You can add 1kg of edible salt, 0.5kg of sodium pyrophosphate, 0.5kg of citric acid, and 1kg of glucose powder. The blanching time is generally 2 minutes. This machine has a timing function.

How long does it take to fry? What is the frying temperature?

General frying 5min, oil temperature at 160-180℃.

Can the temperature of the blanching machine and fryer be adjusted?

Adjustable.

What is the machine material for the potato chips making machine?

All 304 stainless steel.

Can you customize a plan for me according to my plant area?

Yes, we will supply complete potato chip solutions from A to Z based on your processing requirements.

What is the general delivery time of your machines?

If all chip machines are in stock, it will take about 10 days, if not, generally need about 15-30 days.