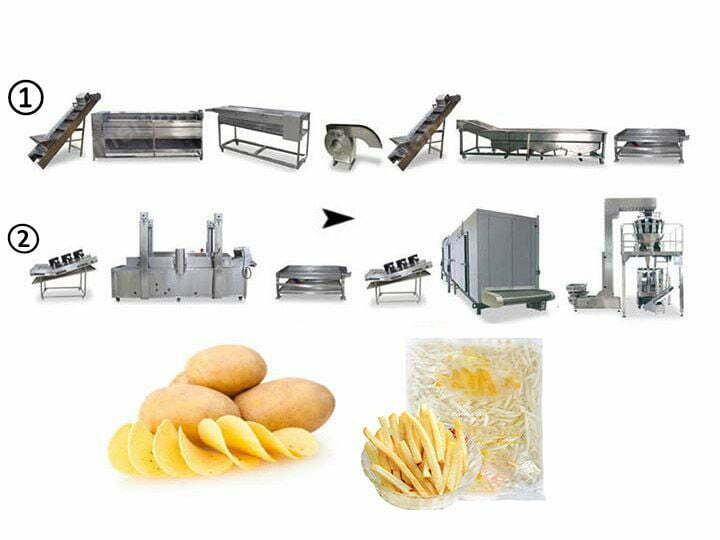

French fries are a very popular fast food and leisure food in a large number of countries. Quick-frozen french fries are common potato products processed by peeling, cutting, blanching, drying, quick-frying, oil removing, and quick-freezing. Frozen half-fried french fries are often delivered to fast-food restaurants to be fried and ready to eat. The fully automatic french fries machine has the advantages of automatic, specialized, and large production, reasonable investment, low energy consumption, multiple functions, simple operation, convenient use, maintenance, etc. The complete frozen french fries production line consists of cleaning and peeling, cutting, blanching, dehydration, frying, degreasing, freezing, packaging, and auxiliary equipment. The automatic french fries making machine is suitable for the production of medium and large-scale french fries processing enterprises.

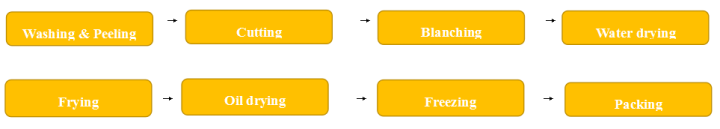

Frozen French fries manufacturing process

1. Wash and peel: Clean the silt on the surface of the potatoes and remove the skin of the potatoes

2. Cut into strips: Cut the potatoes into strips with a size of about 3mm-12mm.

3. Blanch: Blanch the cut fries to protect the color, otherwise the potatoes will be oxidized and turn brown

4. Dehydrate: remove excess water before frying to facilitate frying and improve the taste.

5. Fry: The continuous frying machine in the fully automatic french fries machine automatically controls the temperature for frying, and the temperature is 160-180 degrees Celsius. It usually takes 40-60 seconds to fry.

6. Deoil: The centrifugal deoiling machine deoils the freshly fried French fries, which overcomes the defects of high oil content and greasy taste of the French fries.

7. Quickly freeze: French fries need to be frozen in the freezer at minus 40 degrees Celsius for 15 to 45 minutes. French fries are frozen and shaped for easy storage and subsequent sale and processing.

8. Automatically pack: The automatic packing machine can quickly pack the french fries according to the set weight.

Video of fully automated french fries manufacturing line

Market advantages of fully automatic french fries machine

- Machine material: the machines in the fully automatic frozen french fries processing line are made of 304 stainless steel. It meets food safety standards.

- Superior performance: the automatic french fries making machine is easy to operate, really realize the automatic and stable operation, and high efficiency.

- Easy to operate and maintain, and labor saving. The operation and maintenance is convenient. We offer all-around after-sales service.

- Technical support. For early-stage entrepreneurs, we can provide free production formula and comprehensive technical support to our customers.

Specification of 500kg/h automatic french fries production line

| Machine name | Machine functions | Model: 500kg/h |

| Hoist | Automatic lifting and feeding, convenient, efficient, and fast, saving manpower | Size: 2500*1050*1400mm Length of roller: 800mm Power: 0.75kw Material:304SS |

| Potato Washing And Peeling Machine | Fully automatic potato cleaning and peeling machine, high efficiency and energy saving, saving time and effort | Size: 3600*850*900 mm Length of roller: 2600mm Power: 5.5kw Material:304SS |

| Manual picking belt | Remove the bad pits and scars of the potatoes to improve the quality | Size: 4000*1050*800mm Length of roller: 800mm Power: 1.1kw Material:304SS |

| French Fries Cutter Machine | Efficient strip cutting with adjustable size | Size: 850 * 850 * 1000 mm Power: 0.75kw Cutting strip size: 3-8mm Material:304SS |

| Hoist | Lift the potato strips to the potato blanching machine | Size: 2500*1050*1400mm Length of roller: 800mm Power: 0.75kw Material:304SS |

| Potato Blanching Machine | Remove the starch on the surface of potato strips and inhibit the activity of active enzymes | Size: 8000*1350*1250mm Mesh belt width: 1000mm Electric heating power: 240 kw Material:304SS |

| Water Drying Machine | Remove the scraps that are too small and vibrate to remove excessive water | size:1000*1200*1100mm Mesh belt wideth:1000mm weight:420kg power:21kw |

| French Fries Frying Machine | Continuously fry the french fries under precise temperate control and time control | Size:10000*1450*1550mm Mesh belt width: 1000mm Electric heating power: 320 kw Material:304SS |

| Oil Dryer Machine | Vibrate to remove excessive oil to improve the taste and convey the material to next machine | size:1200*700*750mm weight:420kg power:2.2kw |

| Air drying machine | Blow off extra oil on the surface and cool the fries well enough to go into the quick freezer | Power:7.5KW,380V/50Hz Number of fans: 10 Size:3500x1200x1400mm |

| Quick Freezer | French fries are frozen for about 15-45 minutes for easy storage and transportation | Length: 15000mm Freezing center temperature: – 18 ° Material: 304SS |

| Automatic packing machine | Fully automatic packaging of frozen fries according to customer requirements | Maximum weight: 1000g Single weighing range: 10-1000g Weighing speed:60times/min |

The above is the general technical data of the 500kg/h fully automatic french fries machine. We also offer french fries machines of other capacities ranging from 50-2000kg/h. If special needs are needed, customized services can be provided.