The frozen french fries production line contains professionally designed french fries making machines to manufacture frozen french fries from raw potatoes. The fries production process mainly includes potato washing and peeling, french fries cutting, blanching, drying, frying, oil drying, freezing, and packaging. The French fries production line features high efficiency, high-quality products, various outputs, cost-effectiveness, easy operation, etc.

According to the output, the french fry processing plants can be divided into the small semi-automatic french fries processing line and fully automatic french fry plant. The general output of the small-scale french fries production line is 50kg/h, 100kg/h, 200kg/h, and 300kg/h. The output range of the fully automatic frozen french fries production line is 300kg/h-2t/h.

As a French fries production line manufacturer, we offer whole sets of french fries making machines, as well as single machines, and supporting equipment, and also provide customized machines to match customer needs. French fries processing plant is suitable for snack food factories, restaurants, hotels, food workshops, fast food stories, and so on.

Frozen French fries production line overview

Application: Mainly used to produce frozen french fries, potato chips, finger chips, french-fried potatoes

Output: French fries production line has semi-automatic and fully automatic production lines. The small-scale french fry line’s output is 50-300kg/h, and the output of the fully automatic line is 300-2000kg/h

Customized or not: yes

Heating method: electric heating, gas heating

Popular areas: Turkey, Germany, Italy, Algeria, Saudi Arabia, Iraq, and other places

Production process: Hoist-cleaning and peeling-selection-cutting potato strips-hoist-removing impurities-blanching-dehydration-frying-degreasing-freezing-packaging.

Frozen chips processing plant 3D version video

Semi-automatic frozen french fries production line process

- Potato washing & peeling

size:1600*850*800 mm

power:0.75kw

capacity:200kg/h

weight:280kg

The potato washing and peeling machine has washing and peeling functions. The brush rollers inside the machine can fully peel the potatoes, and they won’t damage the potatoes. The washing time is around 5-6 minutes.

- French fries cutting

size:950*800*1600mm

cutting size:6*6mm to max 15*15mm(it can be customized)

power:1.1kw

capacity:600-800kg/h

This french fries cutter machine is to cut potatoes into strips. The potatoes firstly are cut into slices, and then cut into strips. The size of the potato strip is adjustable, which can be achieved by changing the gap between the blades. Usually, most customers prefer the size of 8*8mm and 9*9mm, and its range is 6*6mm to a max 15*15mm. By the way, the blades are vulnerable to spare parts, so I strongly recommend you buy extra blades.

- Blanching

size:1200*700*950mm

power:12kw

weight:120kg

capacity:100 kg/h

The blanching machine is to remove the starch of the potato strips so that the final french fries bear bright color and better taste. The heating mode of it includes electric heating and gas heating, and you can choose anyone on the basis of your situation. The blanching temperature is 80-100℃. It has an automatic temperature control system, and the temperature is adjustable.

- De-watering

size:1100*500*850mm

power:1.5kw

weight:150kg

capacity:200kg/h

The de-watering machine can prevent the surface of the blanched fries from containing too much water and splashing. It uses the centrifugal principle for dehydration, and the dehydration time can be timed. Generally, the blanching time is 1 to 2 minutes. Besides, an air drying machine is often used in the frozen french fries production line, which can continuously remove the water from the surface of potato strips with strong air.

- French fries frying

size:1200*700*950mm

power:24kw

weight:120kg

capacity:100 kg/h

Frying is an important step in the frozen french fries production line. The frying temperature of 160-180℃ and the potato strips need to fry for 40-60s. This french fries frying machine bears high quality compared with other machines in the market.

- French fries de-oiling

size:1100*500*850mm

power:1.5kw

weight:350kg

capacity:200kg/h

After frying, you should use a deoiling machine to remove the much oil on the surface of the fried potato strips. The deoiling machine is as same as dewatering machine.

- Frozen french fries

A quick freezer machine is to freeze the fried French fries so that they won’t stick to each other when packing. The freezing time is 20-30minuts, and the minimum temperature is -45℃. The French fries we usually eat at McDonald’s are fried again out of the freezer machine. The machine size can be customized according to requirements.

- French fries packaging

A french fries packaging machine is to pack various snacks, with the multiful functions of automatic weighing, packaging and sealing. We offer vacuum potato chips packaging machine and ten-bucket potato chips packing machine.

Semi-automatic french-fried potatoes working video

Small-scale french fry processing machines’ features

Our small-scale frozen french fries production line has many outstanding features:

1. The potato cleaning machine in the small frozen French fries production line has two functions of cleaning and peeling. The brush roller inside the machine can completely peel the potatoes without damaging them. The washing time is about 5-6 minutes. In addition, it can also clean other fruits and vegetables such as ginger, dates, and carrots.

2. The French fries cutting machine in the semi-automatic frozen French fries production line is made of imported components from Taiwan. Its cutting range is 6*6mm~15*15mm. Of course, we can customize multiple cutting-size blades according to customer needs. By changing the blade, you can use one French fries cutter to make multiple sizes of French fries.

3. Both the blanching machine and frying machine in this production line have electric and gas heating methods. Their electric heating tubes are composed of seamless heating tubes, and their power is low. The use of seamless heating tubes can make the blanching machine and fryer have safe and efficient functions.

4. The freezer is the most important machine that distinguishes the frozen French fries production line from the potato chip production line. The freezer can be equipped according to customer needs.

100kg/H Semi-Automatic Frozen French Fries Processing Machine

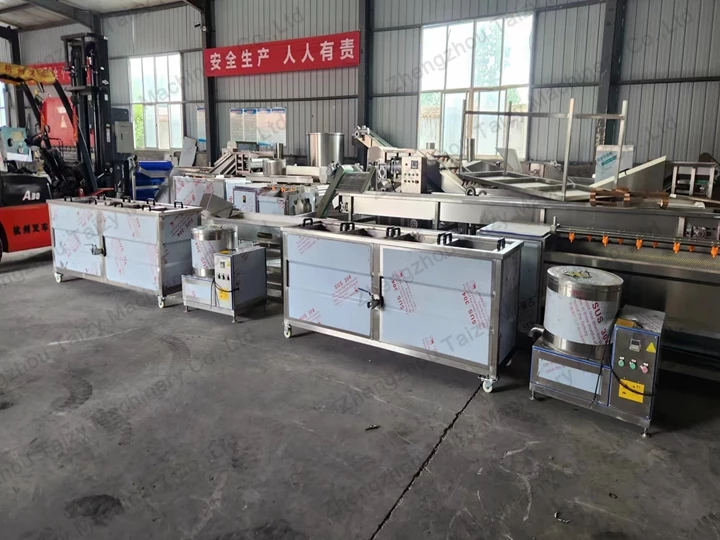

Fully automatic french fry plant process

Compared with the semi-automatic frozen french fries production line, the automatic fries production line replaces the automatic fries machine. In addition, it also adds a fries picking machine and a washing machine before the blanching machine.

And this is what distinguishes the frozen French fries production line from the potato chip production line. It also can produce potato chips by adding or reducing individual machines on the basis of the french fries production line.

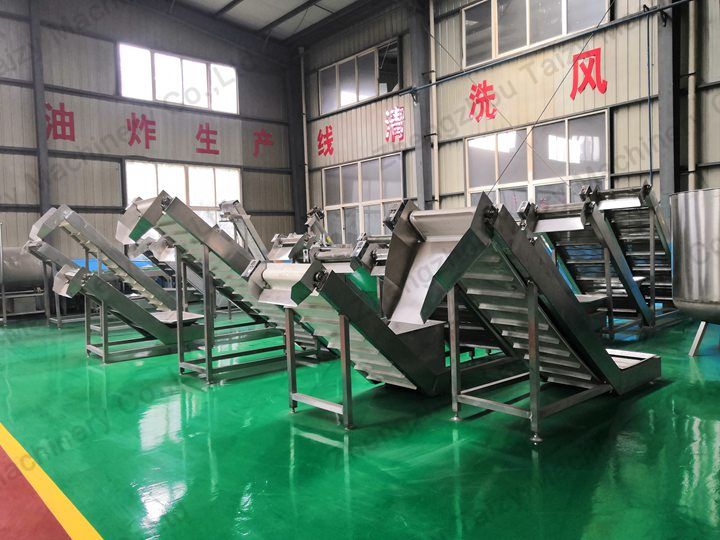

The machine required in the fully automatic frozen french fries processing plant

As shown in the table, there is a series of machines with typical parameters in the automatic frozen French fries production line. In contrast with a semi-automatic french fries processing plant, several hoists, conveyors, and a different type of drying machine and packaging machine are used to realize continuous production and reduce labor. The main machines and supporting equipment can be flexibly adjusted according to actual needs.

| Item | Picture | Parameters |

| 1. hoist machine |  | Model: TZ-100 Power:0.55kw Voltage:380v/50Hz Weight:180kg Size:1500*800*1600mm Belt speed: adjustable Material: 304 stainless steel |

| 2. washing and peeling |  | Model: TZ-2600 Power:4.37kw Voltage:380v/50Hz Weight:480kg Size:3400*1000*1400mm Inside screw speed: adjustable Capacity:2400kg/h Material: 304 stainless steel |

| 3. picking conveyor |  | Model: TZ-110 Power:0.75kw Voltage:380v/50Hz Weight:280kg Size:3500*800*900mm Belt speed: adjustable Material: 304 stainless steel |

| 4. potato cutter |  | Model: TZ-600 Power:1.1kw Voltage:380v/50Hz Weight:120kg Size:950*800*950mm Capacity:600kg/h Material: 304 stainless steel Notes: price only includes 1 set of blades, if want a different size, change the blade. |

| 5. water bucket hoist |  | Model: TZ-200 Power:0.75kw Voltage:380v/50hz Weight:330kg Size:1500*800*1600mm Mesh belt: 500mm Material: 304 stainless steel |

| 6. selecting machine |  | Model: TZ-1400 Size:2400*1000*1300mm Power:1.1kw Voltage:380v/50hz Material: 304 stainless steel Function: Select a different potato size, which will make the final potato size the same. |

| 7. rising machine |  | Model: TZ-4000 Power:4.1kw Voltage:380v/50Hz Weight:400kg Capacity:800kg/h Size:4000*1200*1300mm Belt width: 800mm Material: 304 stainless steel |

| 8. blanching machine |  | Model:TZ-6000 weight: 1200kg size:5000*1200*2400mm Capacity:600kg/h Temperature: 95 degree Belt width:800mm Heating type: Electric Burner power:500000kcal Material: 304 stainless steel |

| 9. water vibrate remover |  | Model: TZ-800 Power:0.5kw Voltage:380v/50Hz Size:1800*1000*900mm Material: 304 stainless steel |

| 10. air cooler |  | Model: TZ-300 Power:6.5kw Voltage:380v/50Hz Weight:700kg Size:4000*1200*1600mm Fan:8pcs Fan power:0.75kw Wind pressure:120pa Speed:2800r/min Belt width: 800mm Material: 304 stainless steel |

| 11. hoist |  | Model: TZ-120 Power:0.75kw Voltage:380v/50hz Weight:180kg Size:1500*800*1300mm Material: 304 stainless steel |

| 12. frying machine |  | Model: TZ-6000 weight: 1200kg size:6000*1200*2400mm Capacity:600kg/h temperature: 95 degree Belt width:800mm Heating type: Electric Burner power:500000kcal Burner brand: Italy liya road Material: 304 stainless steel |

| 13. oil tank |  | Oil pump motor power: 1.5KW/ 380V/50Hz Size: 1400*1300*1850mm Material:304 stainless steel, the oil storage tank is equipped with a heating function, with a filter, and the thickness is 3mm, with an insulation layer. |

| 14. oil filter |  | Coarse filter tank diameter: 300mm Fine filter tank size: 450mm Circulating pump:1.5kw |

| 15. fuel tank |  | 1. The fuel tank is equipped with a heating device. 2. The oil that needs to be added is heated to a certain temperature through the heating tube, and then sent to the inside of the fryer through a circulating pump to achieve the purpose of adding oil. |

| 16. oil vibrate remover |  | Model: TZ-800 Power:0.5kw Voltage:380v/50Hz Size:1800*1000*900mm Material: 304 stainless steel |

| 17. air cooler |  | Model: TZ-300 Power:6.5kw Voltage:380v/50Hz Weight:700kg Size:4000*1200*1600mm Fan:8pcs Fan power:0.75kw Wind pressure:120pa Speed:2800r/min Belt width: 800mm Material: 304 stainless steel |

| 18. hoist |  | Model: TZ-120 Power:0.75kw Voltage:380v/50hz Weight:180kg Size:1500*800*1300mm Material: 304 stainless steel |

| 19. freezer |  | Model: TZ-10000 Out size:160000*3300*2600mm Compressor:150hp Power of mesh:2.2kw Fan:12pcs *1.5kw Mesh belt motor:Siemens PLC: Siemens SUS 304 Inner box thickness:0.8mm External thickness:0.8mmInner Insulation cotton;120mm Compressor: Germany Bitzer One unit:30PTotal 3 units in parallel Note: Price with compressor price |

| 20. packing machine |  | A.Feed conveyor Delivery value:3-6m³/h Voltage:380v Weight:500kg B.TZ-720 Vertical AutomaticPackaging Machine Bag length:100-400mm(L) Bag width:180-350mm(W) Max width of roll film:720mm Packing speed:5-50bags/min Measuring range:6000ml(Max) Air consumption:0.65Mpa Gas consumption:0.4m³/min Voltage:220VAC/50HZ Power:5kw Dimension:1780*1350*1950mm Notes: Includes bag of former C.10 buckets multi-head weighted Machine Maximum weighing:1000g Single weighing range:10-1000g Weighing accuracy:±0.3~1.5g Weighing speed: Max 3000cc Control unit:8.4 inch key screen D.PlatformNon-slip countertop, guardrail around, practical and safe. E.Finished product conveyor |

| 21. french fries freezing storage 10tonns, -20°C |  | Size:5*5*2.4m 100mm color steel polyurethane insulation board: 98m² Kumen: 1 The unit increases the heat dissipation of 80 radiators 8 horses: 1 set Air cooler: 1 Computer automatic defrosting control cabinet: 1 set Solenoid valve: 1 Expansion valve: 1 Freon: 25kg Library body connectors and sealing decoration materials: 71m² Line trunking and moisture-proof lighting, etc.: 1 group Piping system and insulation: 1 set |

Fully automatic frozen french fries production line working video

Characteristics of automatic potato french fries line

- The full-automatic French fries production line, adds many elevators connecting two automatic potato processing machines. Therefore, the automated French fries production line only needs one or two people to control the machine display screen to operate.

- In order to thoroughly clean the impurities on the potato chips, the production line adds a washing machine for selecting the size of the finger chips. The picking machine can pick out the fit-size french fries, and the smaller fries will fall off. This ensures the quality of the French fries. The machine is also the biggest sign that distinguishes the French fry plant and the chips line.

- It adopts the vibrate de-water and de-oiling machine in the processing plant. Compare with the small fries line, it can convey fries to the next machine while achieving de-water and de-oiling functions. And it can realize the function of automatic collection of water or oil.

- The fully automatic frozen french fries production line uses a continuous blanching and french fries frying machine. The machine has the functions of automatic material transfer, controllable frying temperature and time, automatic cleaning of the bottom of the machine, and oil fume collection.

- The size of the frozen fries freezer needs to be determined according to the customer’s production output. In addition, we provide a variety of types of packaging machines, which can achieve large-volume, multi-batch, quantitative packaging. The customer needs to provide the size and weight of the packaging.

Precautions for developing frozen fries business

1. First of all, you should clearly know the final product you need to make and its size. The sizes of frozen French fries in different regions are not exactly the same. The most popular size of French fries is 3-7mm, but there are certain differences in the most popular size in various places.

2. Before starting the fries production business, you should conduct a detailed investigation of the local fries market to profit from the production of fries. For example, the varieties of potatoes and their prices, availability, etc.

3. You can choose the fries production line that suits your production situation according to your factory situation or budget. No matter what production line you choose, we can make a unique production plan for you according to your factory.

How to start a french fries business during a pandemic?

During the pandemic, the production and sales of many factories have been affected to a certain extent. However, some popular brands have managed to expand their business. It is helpful to know about effective strategies for the start-up of the french fries business during the pandemic to grow your business.

Specific sales cases of frozen french fries production lines

Fully automatic french fries production line running in Turkey

French fries machine in Australia

Egyptian customers visited our french fries production machine factory

The customer from Iraq bought 200kg/h fully automatic French fries production line

Welcome to visit Taizy french fries machine factory